Organic fertilizer production line is mainly used to produce organic fertilizer, the use of a variety of organic raw materials and nitrogen, phosphorus, potassium raw materials. Before starting an organic fertilizer plant, you need to investigate the local organic raw materials market, such as the type of raw materials, procurement and transportation methods, transportation costs, etc.

The most important thing to achieve sustainable production of organic fertilizer is to ensure the continuous supply of organic raw materials. Because of the large volume of organic fertilizer plants, it is best to build factories such as large-scale pig farms, chicken farms and so on in places where organic raw materials are abundant.

There are many organic materials to choose from in the organic fertilizer production process, and as an organic fertilizer plant usually choose the most abundant and abundant categories as the main raw material for organic fertilizer production, and with the use of other organic raw materials or moderate nitrogen and phosphorus potassium additives, such as organic fertilizer plant near the establishment of a farm, there is a large amount of agricultural waste every year, the plant wants to choose crop straw as its main raw material and animal waste and peat and zeolite as ingredients.

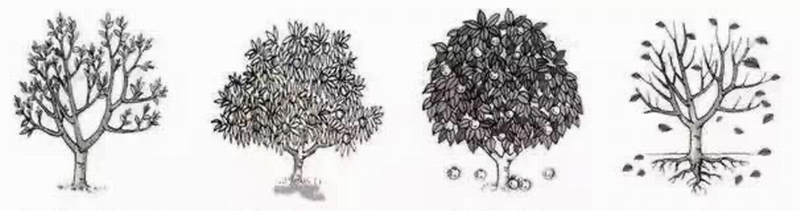

Organic raw materials contain organic matter and nutrients necessary to promote crop growth, and different organic fertilizer production processes can be selected according to local conditions according to different raw material design.

Select the site where organic fertilizer is produced.

Location is very important directly related to the production capacity of organic fertilizer raw materials, etc. , there are the following recommendations:

Location should be close to the supply of raw materials for organic fertilizer production to reduce transport costs and transport pollution.

Choose convenient areas to reduce logistics and transportation costs.

Plant ratio should meet the requirements of production process and reasonable layout, and reserve appropriate space for development.

Stay away from residential areas to avoid organic fertilizer production or raw materials in the transport process more or less produce special odors, affecting the lives of residents.

The site should be flat, geologically hard, low water table and well ventilated. Avoid areas prone to landslides, floods or collapses.

Try to choose policies that are consistent with local agricultural policies and government-supported policies. Make full use of idle land and wasteland without occupying arable land. Make the most of previously unused space so that you can reduce your investment.

The plant is preferably rectangular and should have an area of about 10,000 - 20,000 m2.

Sites cannot be too far from power lines to reduce power consumption and investment in power supply systems. And close to the water source to meet the production, living and fire water needs.

The materials needed for organic fertilizer production, especially poultry manure and plant waste, are obtained as easily as possible from nearby farm pastures such as 'farms' and fisheries.

Post time: Sep-22-2020