There is a very important equipment during the fermentation phase of organic waste - a dumper that accelerates fermentation in different ways. It mixes the raw materials of different composts to enrich the nutrients of the raw materials and adjusts the temperature and moisture of the heap, thus speeding up the whole fermentation process.

The function of the dumper.

As the core equipment of dynamic aerobic composting, the dumper has the following functions:

1. In order to adjust the carbon-nitrogenratio, pH and moisture content of raw materials during fermentation, a small amount of accessories need to be added, and the main material and accessories are mixed in a certain proportion, by the dumper in the process of continuous stacking to achieve uniform mixing.

2. Adjust the temperature of the reactor, the dumper in the course of work, can make the raw material and air fully contact and mix to regulate the temperature of the reactor. Air helps aerobic microorganisms actively generate fermentation heat to increase reactor temperature. At the same time, in the case of high reactor temperature, the dump makes fresh air constantly enter the heap, thus reducing the reactor temperature. A variety of beneficial microorganisms grow and reproduce within the appropriate temperature range.

3. To improve the breathability of the reactor, the dump can also crush the viscous raw material into small pieces, so that the heap is fluffy and elastic, with an appropriate pore rate, which has become an important standard to measure the performance of the dumper.

4. Adjust the water content of the compost and limit the water content of the fermentation raw materials to 55%. During fermentation, biological and chemical reactions produce new moisture, and the consumption of raw materials by microorganisms also causes water to break down due to the loss of carriers. At the same time, the dumper can force the discharge of steam.

5. To meet the special requirements of the fermentation process, such as the dumper can achieve the requirements of raw material crushing or shift continuous dumping.

The composting machine makes fermentation simpler and shorter cycles, and achieves the desired fermentation effect by turning over the heap. The following are several common dumping machines that can quickly and efficiently dispose of organic waste and accelerate the fermentation process of organic raw materials.

The classification of the dumper.

Hydraulic dumper.

This hydraulic series composter includes track-type full-hydraulic dumper, track-type hydraulic auxiliary dumper and wheel-type hydraulic auxiliary dumper, which is faster, more efficient and more practical. The composting machine has the characteristics of compact design, simple operation and saving production space, and can be easily used for fermentation of different raw materials in different fields such as animal and poultry manure, living sludge, kitchen waste, agricultural organic waste, etc.

Slot dumper.

Using chain drive and rolling support plate structure, turn resistance is small, energy saving, suitable for deep tank composting operations. The crushing ability is strong, and the oxygenation effect of the heap is good. Its lateral and longitudinal displacement units enable dumping anywhere in the groove and are very flexible to operate. But it also has limitations, it has to be used with fermentation tanks, so choosing this dumper requires a matching fermentation tank.

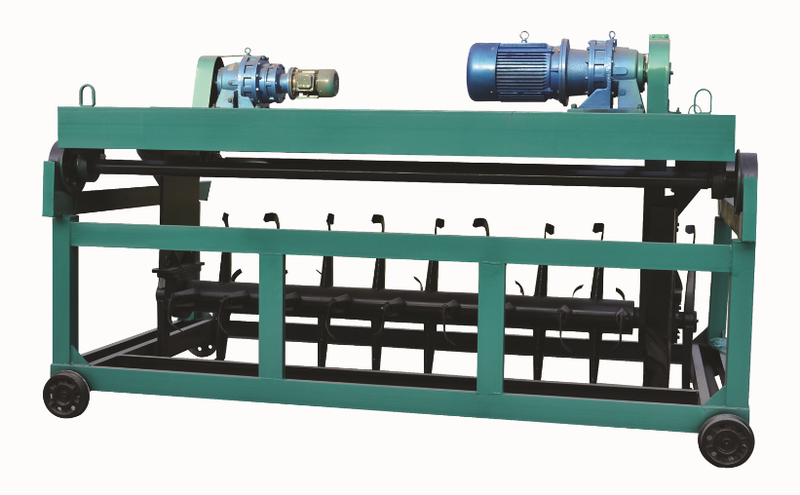

Walking dumper.

Driven by four wheels, the dumper is suitable not only for outdoor open areas, but also for workshops and indoors. Adaptable, safe and reliable, easy to maintain. According to the principle of aerobic fermentation, enough oxygen is provided for the reproduction of aerobic microorganisms.

How to select a dumper.

The performance of the dumper is determined by its dump speed and the size of the heap that can be handled.

Choose the dumper according to the size of the actual raw material heap and the amount of the dump. Higher-powered, higher-configuration dumpers typically have greater throughput to handle larger piles of raw materials.

Also consider the space required for compost machine walking. A self-driving dumper saves more space than a drag dumper.

Of course, prices and budgets also affect the selection of composting equipment. The greater the production capacity, the higher the price, the need to choose the most suitable model according to actual production needs.

Post time: Sep-22-2020