Introduction of Organic Fertilizer Production Line

Generally, organic fertilizer production line divides mainly into 2 prats: pre-processing and granules producing. The main equipment on pre-process is compost turner. There are three kinds of fertilizer compost turners being provided by us – groove type compost turner, self-propelled organic fertilizer compost turning machine, and hydraulic compost turner. They own different characteristics which is more convenient for customers choosing whichever they like.

As for granules producing process, we manufacture high-quality, and high-output fertilizer machines, such as fertilizer mixer, fertilizer crusher, new type organic fertilizer dedicated granulator, fertilizer polishing machine, organic fertilizer screening machine, fertilizer coating machine, and automatic fertilizer package ect. All of them can meet the demands of large yield and environmental-protection organic fertilizer production.

We manufacture the fertilizer machines by ourselves, so we provide customers with more quality-warranty and energy-saving products. Besides, we can assemble not only organic fertilizer production line with 20,000 tons output, but also 30,000 tons, 50,000 tons, and even larger yield.

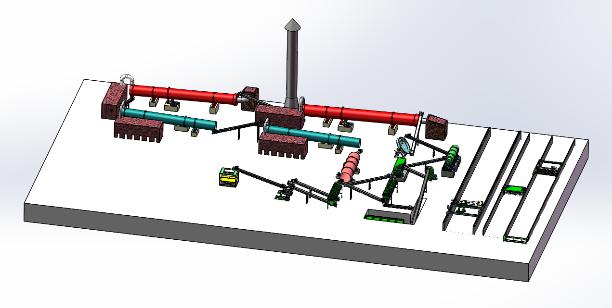

Main components of 20,000 tons per year Organic Fertilizer Production Line

The organic fertilizer production line is mainly made up of compost turner, fertilizer crushing machine, mixing machine, granulation machine, drying machine, cooling machine, screening machine, organic fertilizer coating machine and automatic package ect.

1.Fermentation process

The fermentation of bio-organic raw materials plays quite a fundamental role in the whole production. Sufficient fermentation lays a solid foundation for the quality of the end products. All compost turners mentioned above, each has its merits, Groove type compost turner and groove type hydraulic compost turner can thoroughly compost and turn high-stacked fermentation materials with large production capacity. Self-propelled compost turner and hydraulic compost turner, which are suitable for various organic matters, can work freely outside or inside of the factory, greatly increasing the speed of aerobic fermentation.

2.Crushing process

Our semi-wet material crusher with high-speed rotating blade is a new type and high-efficiency single reversible crusher, and has strong adaptability to high water-content organic matter. Semi-wet material crusher is widely used in the organic fertilizer producing process and it performs well in crushing chicken manure, sludge and other wet materials. This fertilizer crusher greatly shortens the production cycle of organic fertilizer, and saves production cost.

3.Mixing process

After being crushed, raw materials should be mixed evenly before granulating. Double-shaft horizontal mixer is mainly used to humidity and mix powdery materials in the fertilizer industry. As the spiral blades have multiple angles, raw materials can be mixed quickly and effectively, regardless of their shape, size and density. Our double-shaft horizontal mixer with its large capacity, it deeply loved by our clients.

4.Granulating process

Granulating process is a core part in the production line. Our new type organic fertilizer dedicated granulator is a wise and perfect choice for customers granulate high-quality and uniform-shaped organic fertilizers, the purity of which can reach as high as 100%. Different from the conventional ways of producing organic fertilizer. It can make your producing process more efficient and energy-saving.

5.Drying and Cooling process

We manufacture rotary drum dryer and rotary drum cooler for fertilizer drying and cooling. Rotary drum drying machine uses hot air to reduce the moisture content of fertilizers. After drying, the moisture content of compound fertilizer will be reduced from 20%~30% to 2%~5%. It adopts new combined type lifting board to avoid materials wine tunnel phenomenon, which helps to improve the heating efficiency.

The fertilizer cooler has been an essential and indispensable part in the whole fertilizer processing. The rotary drum cooling machine is used for cooling fertilizer with certain temperature and particle size in fertilizer industry. By the cooling process, the material can be removed about three percent of the water. It also can combine with the rotary dryer to remove the dust and clean the exhaust together, which can improve the cooling efficiency and the rate of thermal energy utilization, reduce labor intensity, and further remove moisture of fertilizer.

6.Screening process

After cooling, there is still powdered materials in the end products. All fines and large particles can be screened out using our rotary drum screen machine. Then, fines being transported by belt conveyer are back to horizontal mixer for remixing and re-granulating with raw materials. While large particles need to be crushed in chain crusher before re-granulation. Quasi-finished products are conveyed into organic fertilizer coating machine, in this way, a complete production cycle is formed.

7.Packaging process

This is the last process. Our automatic quantitative fertilizer packager is an automatic and intelligent packager which is specially designed, manufactured and tailored to different irregular materials and granular material’s needs. Weighing control system is designed in accordance with the requirements of dust-proof and waterproof. Feed bin also can be equipped according to customer’s demands. It is suitable for large-volume sub packaging of bulk materials, and is automatically weighed, conveyed, and sealed in bags.

Advantages of 20,000 ton per year Organic Fertilizer Production Line

1) High output

With an annual production capacity of 20,000 tons of organic fertilizer production line, annual disposal volume of excrement can reach 80,000 cubic meters.

2) Best quality of finished fertilizer

Taking livestock manure for example, the overall excrement of a pig per year with a combination of bedding materials can macerate some 2000~2500 kilograms high-quality organic fertilizer, containing 11%~12% organic matters(0.45% nitrogen, 0.19% diphosphorous pentoxide and 0.6% potassium chloride etc.), which is enough for an acre of field to meet its demand on fertilizer all the year around.

The resulting fertilizer produced by our organic fertilizer granulation riches in various nutritive components with the content of above 6%, including nitrogen, phosphorous, potassium etc. Its content of organic matters is above 35%, both of which are higher than national standard.

3) Great market demand brings the good profitability

An organic fertilizer production line can meet the demand of fertilizer for the locals as well as the neighboring market. Bio-organic fertilizer is widely used in farm fields, fruit trees, landscaping, upscale turf, soil improvement and other areas.

Post time: Sep-27-2020