Manure composting machine

A manure composting machine is a specialized equipment designed to efficiently manage and convert manure into nutrient-rich compost. This machine plays a crucial role in sustainable agriculture, providing a solution for effective waste management and transforming manure into a valuable resource.

Benefits of a Manure Composting Machine:

Waste Management: Manure from livestock operations can be a significant source of environmental pollution if not managed properly. A manure composting machine helps mitigate this issue by efficiently converting manure into compost. This process reduces odors, eliminates pathogens, and minimizes the risk of water and air pollution.

Nutrient Recycling: Manure contains valuable nutrients such as nitrogen, phosphorus, and potassium. By composting manure, these nutrients are preserved and transformed into a stable form that can be easily utilized by plants. Compost derived from manure acts as a natural fertilizer, enriching the soil and promoting sustainable agriculture practices.

Weed and Pathogen Control: Composting manure at the right temperature and for the appropriate duration helps destroy weed seeds, pathogens, and harmful bacteria present in the manure. This reduces the risk of weed infestation and the spread of diseases, creating a healthier and safer environment for livestock and agricultural practices.

Soil Health and Structure: Compost derived from manure improves soil structure, enhances water retention capacity, and promotes the development of beneficial microorganisms. It increases soil fertility, enhances nutrient availability, and helps restore degraded soils, contributing to sustainable land management practices.

Working Principle of a Manure Composting Machine:

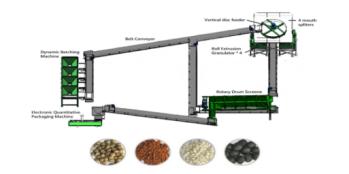

A manure composting machine typically consists of a mixing system, a temperature control system, and an aeration system. The mixing system ensures proper blending of manure with other composting materials, such as straw, sawdust, or crop residues. The temperature control system helps maintain the composting process at an optimal temperature range, typically between 50 to 65 degrees Celsius (122 to 149 degrees Fahrenheit). The aeration system ensures adequate airflow, allowing beneficial microorganisms to thrive and accelerate the composting process.

Applications of Manure Composting Machines:

Livestock Farms: Manure composting machines are essential on livestock farms to manage the large volumes of manure generated. These machines enable farmers to transform manure into compost, reducing waste and odors while harnessing the nutrient-rich properties of manure for sustainable soil fertility.

Agricultural Practices: Compost derived from manure is widely used in agricultural practices. It can be applied as a soil amendment to improve soil health, enhance crop productivity, and reduce the reliance on synthetic fertilizers. Composting manure not only helps recycle nutrients but also reduces the risk of nutrient runoff and contamination of water bodies.

Horticulture and Landscaping: Manure composting machines are valuable in horticultural and landscaping applications. Compost derived from manure can be used to enrich potting mixes, improve soil quality in gardens and flower beds, and enhance the growth of ornamental plants, trees, and shrubs.

Environmental Conservation: Manure composting machines contribute to environmental conservation efforts by reducing the environmental impact of manure management. Properly composting manure minimizes methane emissions, reduces the risk of water contamination, and helps prevent the release of harmful substances into the environment.

A manure composting machine is a vital tool for efficient organic waste management and nutrient recycling. By converting manure into compost, these machines offer numerous benefits, including waste reduction, nutrient preservation, weed and pathogen control, and improved soil health. Manure composting machines find applications in livestock farms, agricultural practices, horticulture, and environmental conservation initiatives.