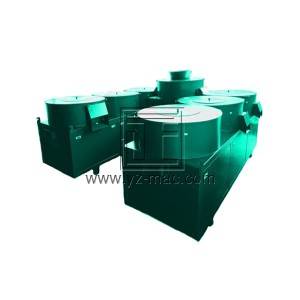

Loading & Feeding Machine

Use of Loading & Feeding Machine as raw material warehouse in the process of fertilizer production and processing. It is also a kind of conveying equipment for bulk materials. This equipment can not only convey fine materials with particle size less than 5mm, but also bulk materials more than 1cm. It has strong adaptability and adjustable conveying capacity and continuous uniform conveying of various materials. The equipment is equipped with anti-smashing net, vibration anti-blocking device, frequency conversion speed regulating device, can achieve uniform discharge and accurate control of discharge volume.

As one process, the Loading & Feeding Machine is used to load materials from forklift. It is widely used for conveying powder, granule or small block materials, usually it could be used with the other machine. It can achieve uniform and continuous discharging to saving labor and improving work efficiency in fertilizer production line.

1. The slot plate adopts double arc plate to effectively prevent leakage.

2. The traction chain adopts a structure in which load bearing and traction are separated, which improves the ability of the plate feeder to withstand impact load.

3. The tail tensioning device is provided with a disc spring, which can reduce the impact load of the slow chain and improve the service life of the chain.

4. The chain plate feeder consists of five parts: the head drive device, the tail wheel device, the tensioning device, the chain plate and the frame.

5. The tail has a shock absorber for shock absorbers, and the middle has a special shock absorber roller support to improve the large block. The material is impacted by the impact of the rollers and the groove plates on both sides to improve the life of the running parts.

Loading & Feeding Machine is composed of a weighing system, a chain plate conveying mechanism, a silo and a frame; wherein the chain plate, the chain, the pin, the roller and the like of the conveying mechanism are wearing parts with different strengths and frequencies. The first wear and tear deformation require regular maintenance and replacement; the chain plate feeder has high rigidity and can adapt to a large piece of material with a certain granularity. The volume of the hopper is large, which can effectively shorten the feeding time of the forklift, but at the same time the chain plate transmission speed is slow, bearing great ability.

1. It has big transport capacity and long transport distance.

2. Stable and highly efficient operation.

3. Uniform and continuous discharging

4. The size of the hopper and the model of the motor can be customized according to the capacity.

|

Model |

Power |

Capacity(t/h) |

Dimensions(mm) |

|

YZCW-2030 |

Mixing power: 2.2kw

Vibration power:(0.37kw Output power: 4kw frequency conversion |

3-10t/h |

4250*2200*2730 |

|

YZCW-2040 |

Mixing power: 2.2kw

Vibration power:0.37kw Output power:4kw frequency conversion |

10-20t/h |

4250*2200*2730 |