Livestock manure fertilizer granulation equipment

Livestock manure fertilizer granulation equipment is designed to convert the raw manure into granular fertilizer products, making it easier to store, transport, and apply. Granulation also improves the nutrient content and quality of the fertilizer, making it more effective for plant growth and crop yield.

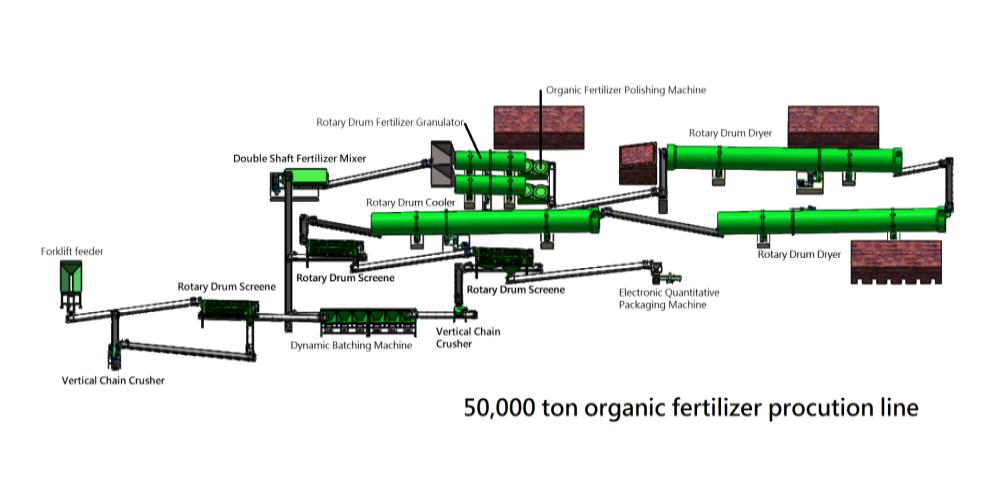

The equipment used in livestock manure fertilizer granulation includes:

1.Granulators: These machines are used to agglomerate and shape the raw manure into granules of a uniform size and shape. Granulators can be either rotary or disc type, and come in a range of sizes and designs.

2.Dryers: After granulation, the fertilizer needs to be dried to remove excess moisture and increase its shelf life. Dryers can be rotary or fluidized bed type, and come in a range of sizes and designs.

3.Coolers: After drying, the fertilizer needs to be cooled to prevent overheating and reduce the risk of moisture absorption. Coolers can be rotary or fluidized bed type, and come in a range of sizes and designs.

4.Coating equipment: Coating the fertilizer with a protective layer can help reduce moisture absorption, prevent caking, and improve the release rate of the nutrients. Coating equipment can be either drum type or fluidized bed type.

5.Screening equipment: Once the granulation process is complete, the finished product needs to be screened to remove any oversized or undersized particles and foreign objects.

The specific type of livestock manure fertilizer granulation equipment that is best for a particular operation will depend on factors such as the type and amount of manure to be processed, the desired end product, and the available space and resources. Some equipment may be more suitable for larger livestock operations, while others may be more appropriate for smaller operations.