Hot New Products Disc Granule Making Machine - Rotary Drum Sieving Machine – YiZheng

Hot New Products Disc Granule Making Machine - Rotary Drum Sieving Machine – YiZheng Detail:

Rotary Drum Sieving Machine is mainly used for the separation of the finished products (powder or granules) and the return material, and can also realize the grading of the products, so that the finished products (powder or granule) can be evenly classified.

It is a new type of self-cleaning material-screening special equipment. It is widely used in screening various solid materials that granularity less than 300mm. It has high efficiency, low noise, small amount of dust, long service life, less maintenance, easy maintenance and many other features. The screening capacity is 60 tons / hour ~1000 tons / hour. It is an ideal equipment in the production process of organic fertilizer and compound fertilizer.

The self-clearing Rotary Drum Sieving Machine performs reasonable rotation of the equipment center separation cylinder through the gearbox type deceleration system. The center separation cylinder is a screen composed of several annular flat steel rings. The center separation cylinder is installed with the ground plane. In the inclined state, the material enters the cylinder net from the upper end of the central separation cylinder during the working process. During the rotation of the separation cylinder, the fine material is separated from the top to the bottom through the screen interval composed of the annular flat steel, and the coarse material is separated from the lower end of the separation cylinder and will be transported into the crusher machine. rThe device is provided with a plate type automatic cleaning mechanism. During the separation process, the screen body is continuously “combed” by the cleaning mechanism through the relative movement of the cleaning mechanism and the sieve body, so that the sieve body is always cleaned throughout the working process. It will not affect the screening efficiency due to the clogging of the screen.

1. High screening efficiency. Because the equipment has a plate cleaning mechanism, it can never block the screen, thus improving the screening efficiency of the equipment.

2. Good working environment. The entire screening mechanism is designed in the sealed dust cover, completely eliminating the dust flying phenomenon in the screening and improving the working environment.

3. Low noise of the equipment. During operation, the noise generated by the material and the rotating screen is completely isolated by the sealed dust cover, which reduces equipment noise.

4. Convenient maintenance. This equipment seals the equipment observation window on both sides of the dust cover, and the staff can observe the operation of the equipment at any time during work.

5.Long service life. This equipment screen is composed of several annular flat steels, and its cross-sectional area is much larger than the screen cross-sectional area of other separation equipment screens.

|

Model |

Diameter (mm) |

Length (mm) |

Rotating Speed (r/min) |

Inclination (°) |

Power (KW) |

Overall Size (mm) |

|

YZGS-1030 |

1000 |

3000 |

22 |

2-2.5 |

3 |

3500×1300×2100 |

|

YZGS-1240 |

1200 |

4000 |

17 |

2-2.5 |

3 |

4500×1500×2200 |

|

YZGS-1560 |

1500 |

5000 |

14 |

2-2.5 |

5.5 |

6000×1700×2300 |

|

YZGS-1860 |

1800 |

6000 |

13 |

2-2.5 |

7.5 |

6700×2100×2500 |

|

YZGS-2070 |

2000 |

7000 |

11 |

2-2.5 |

11 |

7700×2400×2700 |

Product detail pictures:

Related Product Guide:

Pig manure organic fertilizer complete equipment

Compound fertilizer production process

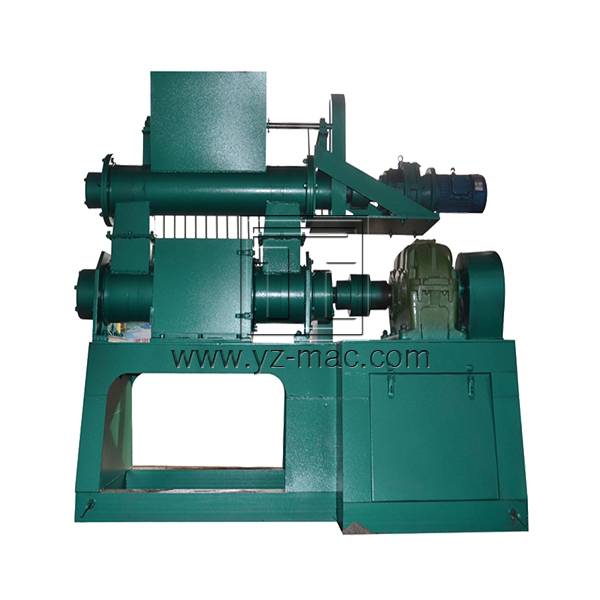

Organic waste composter machine Hot New Products Disc Granule Making Machine - Rotary Drum Sieving Machine – YiZheng , The product will supply to all over the world, such as: Turkey, South Korea, Detroit, The double-shaft chain pulverizer is a new type of pulverizer, which is a special pulverizing equipment for fertilizers. It effectively solves the old problem that fertilizers cannot be pulverized due to moisture absorption. Proved by long-term use, this machine has a series of advantages such as convenient use, high efficiency, large production capacity, simple maintenance, etc. It is especially suitable for the crushing of various bulk fertilizers and other medium hardness materials.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.