Groove Type Composting Turner

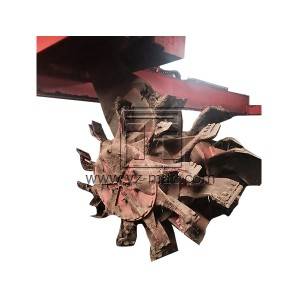

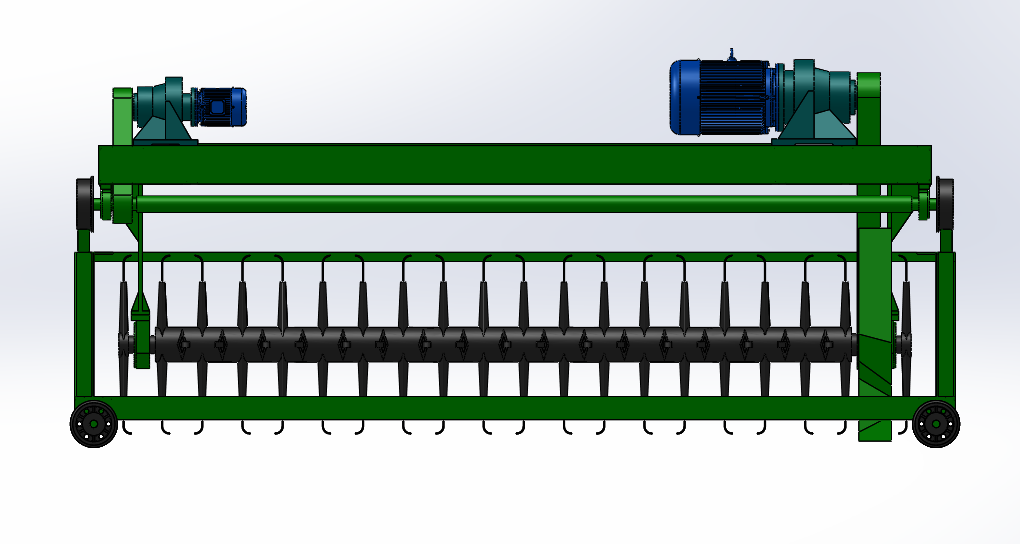

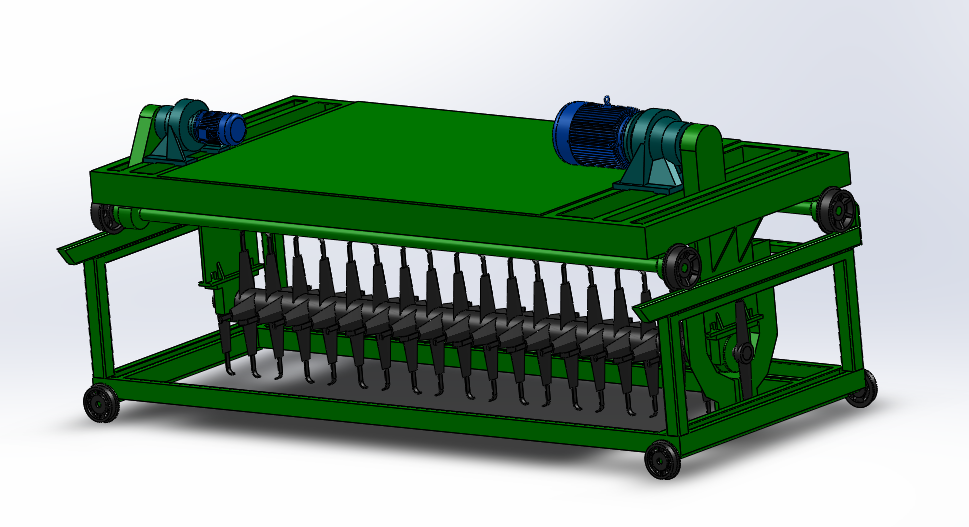

Groove Type Composting Turner Machine is the most widely used aerobic fermentation machine and compost turning equipment. It includes groove shelf, walking track, power collection device, turning part and transfer device (mainly used for multi-tank work). The working portion of the compost turner machine adopts advanced roller transmission, which can be lifted and non-liftable. The liftable type is mainly used in work scenarios with a turning width of no more than 5 meters and a turning depth of no more than 1.3 meters.

(1) Groove type composting turner used for fermentation of organic waste such as livestock and poultry manure, sludge dumpling, sugar plant filter mud, dross cake meal and straw sawdust.

(2) Turn and stir the material in the fermentation tank and move back to play the effect of fast turning and even stirring, so as to achieve full contact between the material and air, so that the fermentation effect of the material is better.

(3) Groove type composting turner is the core equipment of aerobic dynamic composting. It is the mainstream product that affects the development trend of the compost industry.

The importance of Groove type composting turner from its role in compost production:

1. Mixing function of different ingredients

In fertilizer production, some auxiliary materials must be added to adjust the carbon-nitrogen ratio, pH and water content of raw materials. The main raw materials and accessories that are roughly stacked together, the purpose of uniform mixing of different materials can be achieved while turning.

2. Conciliate the temperature of the raw material pile.

A large amount of fresh air can be brought and fully contacted with the raw materials in the mixing pile, which can help aerobic microorganisms to actively generate fermentation heat and increase the pile temperature, and the heap temperature can cool down by the constant replenishment of fresh air. So that form a state of alternation of medium-temperature-temperature-temperature, and various beneficial microbial bacteria grow and reproduce rapidly in the temperature period.

3. Improve the permeability of raw material piles.

The groove type composting turner can process the material into smaller pieces, making the material pile thick and compact, fluffy and elastic, forming a suitable porosity between the materials.

4. Adjust the moisture of the raw material pile.

The suitable moisture content of raw material fermentation is about 55%. In the fermentation of the turning operation, the active biochemical reactions of aerobic microorganisms will generate new moisture, and the consumption of raw materials by oxygen-consuming microorganisms will also cause the water to lose the carrier and free out. Therefore, with the fertilization process, water will be reduced in time. In addition to the evaporation formed by heat conduction, the turning raw materials will form compulsory water vapor emission.

1. It is used in fermentation and water removal operations in organic fertilizer plants, compound fertilizer plants, sludge waste factories, gardening farms and mushroom plantations.

2. Suitable for aerobic fermentation, it can be used in conjunction with solar fermentation chambers, fermentation tanks and shifters.

3. Products obtained from high-temperature aerobic fermentation can be used for soil improvement, garden greening, landfill cover, etc.

Key Factors to Control Compost Maturity

1. Regulation of carbon-nitrogen ratio (C/N)

The suitable C/N for decomposition of organic matter by general microorganisms is about 25:1.

2. Water control

The water filtration of compost in actual production is generally controlled at 50% ~ 65%.

3. Compost ventilation control

Ventilated oxygen supply is an important factor for the success of compost. It is generally believed that oxygen in the pile is suitable for 8% ~ 18%.

4. Temperature control

Temperature is an important factor affecting the smooth operation of microorganisms of compost. The fermentation temperature of high-temperature compost is 50-65 degrees C, which is the most commonly used method at present.

5. Acid salinity (PH) control

PH is an important factor affecting the growth of microorganisms. PH of the compost mixture should be 6-9.

6. Smelly control

At present, more microorganisms are used to deodorize.

(1) The fermentation tank can be discharged continuously or in bulk.

(2) High efficiency, smooth operation, strong and durable.

|

Model |

Length(mm) |

Power (KW) |

Walk Speed(m/min) |

Capacity (m3/h) |

|

FDJ3000 |

3000 |

15+0.75 |

1 |

150 |

|

FDJ4000 |

4000 |

18.5+0.75 |

1 |

200 |

|

FDJ5000 |

5000 |

22+2.2 |

1 |

300 |

|

FDJ6000 |

6000 |

30+3 |

1 |

450 |