Graphite granulation process equipment

Graphite granulation process equipment refers to the machinery and equipment used in the process of granulating graphite material. This equipment is designed to transform graphite into granules or pellets of desired size and shape. The specific equipment used in the graphite granulation process may vary depending on the desired final product and the production scale. Some common types of graphite granulation process equipment include:

1. Ball mills: Ball mills are commonly used to grind and pulverize graphite into fine powder. This powdered graphite can then be further processed into granules.

2. Mixers: Mixers are used to blend graphite powder with binders and other additives to create a homogeneous mixture before granulation.

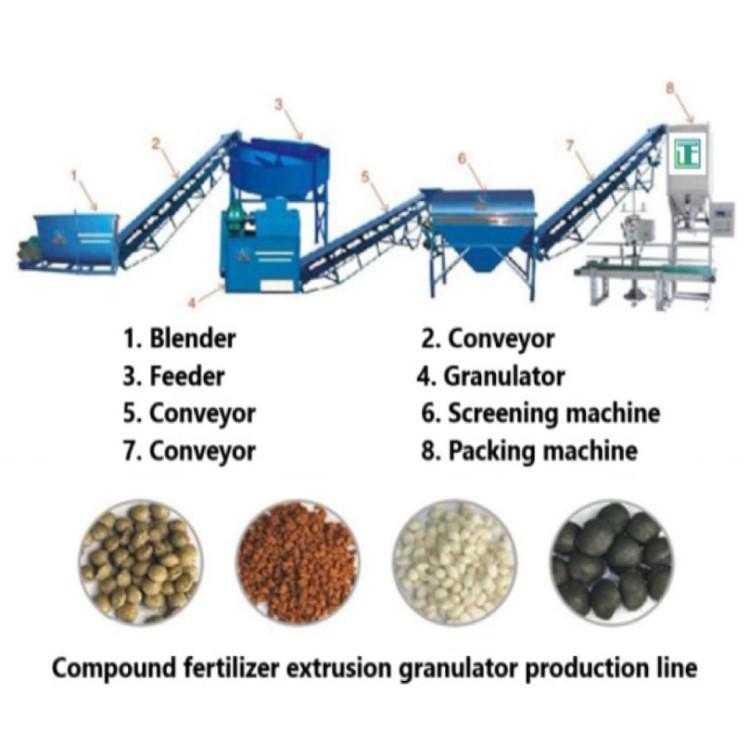

3. Pelletizers: Pelletizers are machines specifically designed to shape and form graphite into pellets or granules. They apply pressure or extrusion force to compact the graphite mixture into the desired form.

4. Rotary dryers: Rotary dryers are used to remove moisture from the graphite granules after the granulation process. This helps to enhance the stability and quality of the granules.

5. Screening equipment: Screening equipment is used to separate and classify graphite granules based on their size. It ensures that the final product meets the required particle size distribution.

6. Coating equipment: Coating equipment may be used to apply a protective or functional coating on the graphite granules to enhance their performance in specific applications.

It’s important to note that the specific equipment and processes used in graphite granulation can vary depending on the desired end-use application, production requirements, and available technologies. Consulting with graphite granulation equipment suppliers or manufacturers can provide more detailed information on the specific equipment suitable for your needs. https://www.yz-mac.com/roll-extrusion-compound-fertilizer-granulator-product/