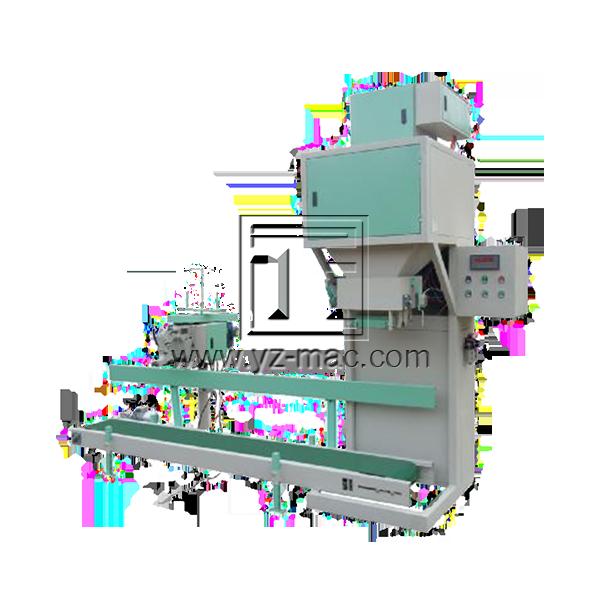

Granulator machine for fertilizer

A fertilizer granulator machine is a specialized equipment designed to convert raw materials into granular forms for efficient and convenient fertilizer production. By transforming loose or powdered materials into uniform granules, this machine improves the handling, storage, and application of fertilizers.

Benefits of a Fertilizer Granulator Machine:

Improved Nutrient Efficiency: Granulating fertilizers enhances nutrient efficiency by providing controlled release and uniform distribution of nutrients. The granules slowly release the nutrients over time, ensuring sustained nourishment for plants and minimizing nutrient loss through leaching or volatilization.

Reduced Moisture Absorption: Granulated fertilizers have a lower moisture absorption rate compared to powdered or loose fertilizers. This reduces the risk of caking and clumping during storage and application, ensuring the integrity and effectiveness of the fertilizer product.

Enhanced Handling and Application: The granular form of fertilizers allows for easy handling, transportation, and application. Granules can be spread evenly across the field using various application methods, such as broadcasting, seeding, or placement, ensuring uniform nutrient distribution and efficient nutrient uptake by plants.

Customizable Formulations: Fertilizer granulator machines offer flexibility in creating customized fertilizer formulations. By adjusting the composition and ratios of raw materials, such as nitrogen, phosphorus, and potassium, specific nutrient requirements can be met, tailoring the fertilizer to the needs of different crops or soil conditions.

Working Principle of a Fertilizer Granulator Machine:

A fertilizer granulator machine operates on the principle of agglomeration, where fine particles are agglomerated into larger granules. This process involves several steps:

Material Preparation: Raw materials, including nitrogen sources (e.g., urea), phosphorus sources (e.g., diammonium phosphate), and potassium sources (e.g., potassium chloride), are thoroughly mixed to create a homogeneous blend.

Moisture Adjustment: The moisture content of the material mixture is adjusted to an optimal level. This is crucial for the formation of granules and ensures proper binding of the particles during the granulation process.

Granulation: The prepared material mixture is fed into the fertilizer granulator machine. Inside the machine, the mixture is subjected to high pressure, rolling, and shaping actions, resulting in the formation of granules. Binders or additives may be added to facilitate granule formation and improve the strength and stability of the granules.

Drying and Cooling: The freshly formed granules are dried and cooled to remove excess moisture and strengthen the granules further. This step ensures the stability and longevity of the granular fertilizer.

Applications of Fertilizer Granulator Machines:

Agricultural Crop Production: Fertilizer granulator machines are widely used in agricultural crop production. The granulated fertilizers provide essential nutrients to crops, promoting healthy growth, increasing yield, and improving overall crop quality.

Horticulture and Gardening: Fertilizer granules are extensively used in horticulture and gardening applications. The controlled-release properties of granulated fertilizers ensure a consistent nutrient supply to plants over an extended period, making them ideal for container plants, greenhouse crops, and ornamental gardens.

Organic Fertilizer Production: Fertilizer granulator machines can also be used in the production of organic fertilizers. By granulating organic materials, such as compost, manure, or bio-based residues, the machines help transform them into uniform granules suitable for organic farming practices.

Fertilizer Blending and Manufacturing: Fertilizer granulator machines are essential in fertilizer blending and manufacturing facilities. They enable the production of high-quality granular fertilizers with precise nutrient compositions, allowing manufacturers to meet specific customer requirements and produce custom fertilizer blends.

A fertilizer granulator machine offers numerous benefits in fertilizer production, including improved nutrient efficiency, reduced moisture absorption, enhanced handling and application, and the ability to create customized fertilizer formulations. By transforming loose or powdered materials into uniform granules, these machines enhance the effectiveness and convenience of fertilizers. Fertilizer granulator machines find applications in agricultural crop production, horticulture, gardening, organic fertilizer production, and fertilizer blending and manufacturing.