Good User Reputation for Pellet Cooler - Counter Flow Cooling Machine – YiZheng

Good User Reputation for Pellet Cooler - Counter Flow Cooling Machine – YiZheng Detail:

The new generation of Counter Flow Cooling Machine researched and developed by our company, the material temperature after cooling is not higher than the room temperature 5 ℃, the precipitation rate is not less than 3.8%, for the production of high-quality pellets, prolong the storage time of pellets and improve the economic benefits played a important role. It is a model widely used abroad and is an advanced replacement of traditional cooling equipment.

When the particles from the drying machine pass through the Counter Flow Cooling Machine, they come into contact with the surrounding air. As long as the atmosphere is saturated, it will take away water from the surface of the particles. The water inside of the particles is moved to the surface via the capillaries of fertilizer granules and then carried away by evaporation, so the fertilizer granules get cooled. At the same time, the heat absorbed by the air, which improves the water carrying capacity. The air is continuously discharged by the fan to take away the heat and moisture of the fertilizer granules in the cooler.

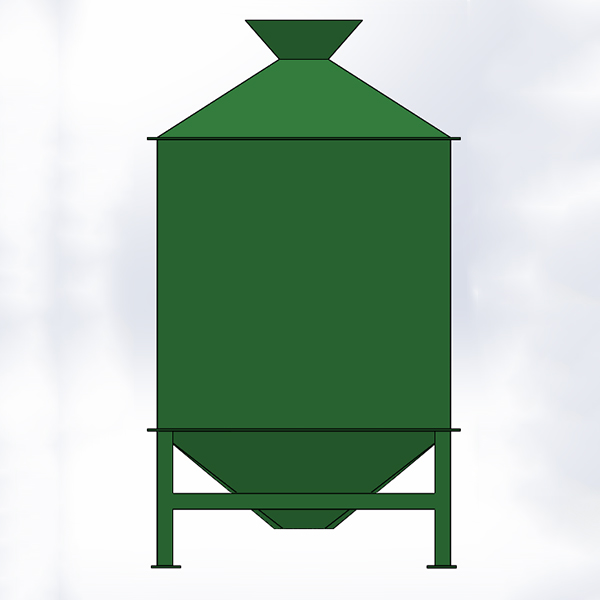

Mainly used for cooling high temperature granular materials after granulation. The machine has a unique cooling mechanism. The cooling air and the high temperature and high humidity materials move in the opposite direction, so that the materials are gradually cooled from top to bottom, avoiding the surface cracking of the materials caused by the general vertical cooler due to the sudden cooling.

The Counter Flow Cooling Machine has good cooling effect, high degree of automation, low noise, simple operation, and low maintenance. It is a model widely used abroad and is an advanced replacement cooling equipment.

Superiority:

【1】The temperature of the cooled particles is not higher than +3 ℃~ +5 ℃ of room temperature; precipitation = 3.5%;

【2】It has the unique function of automatic pellet discharge when shutting down;

【3】Uniform cooling and low degree of crushing;

【4】Simple structure, low operating cost and small space occupation;

|

Model |

NL 1.5 |

NL 2.5 |

NL 4.0 |

NL 5.0 |

NL 6.0 |

NL8.0 |

|

Capacity (t/h) |

3 |

5 |

10 |

12 |

15 |

20 |

| Cooling volume (m) |

1.5 |

2.5 |

4 |

5 |

6 |

8 |

|

Power (Kw) |

0.75+0.37 |

0.75+0.37 |

1.5+0.55 |

1.5+0.55 |

1.5+0.55 |

1.5+0.55 |

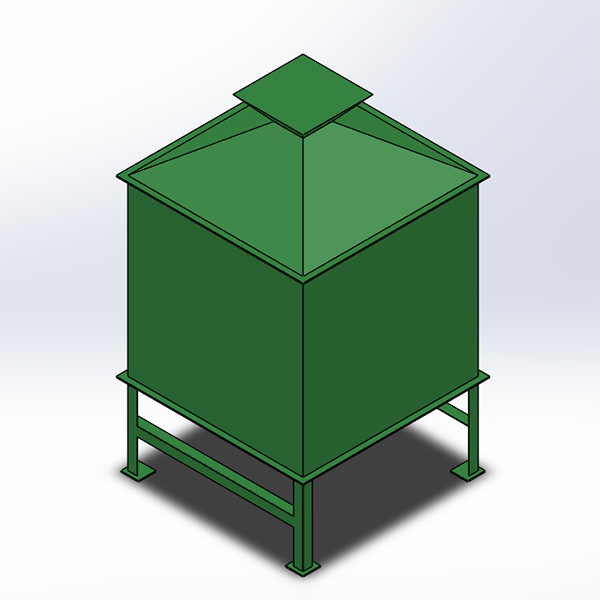

Product detail pictures:

Related Product Guide:

Compound fertilizer production process

Complete production equipment for organic fertilizer

Manufacturer of organic fertilizer turners, develops and produces large, medium and small fermentation turners, wheel turners, hydraulic turners, crawler turners, and turners of good quality, complete equipment, and reasonable prices. Welcome Free consultation. Good User Reputation for Pellet Cooler - Counter Flow Cooling Machine – YiZheng , The product will supply to all over the world, such as: Argentina, Mozambique, Rotterdam, What pits should be avoided when choosing

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!