Fertilizer production line

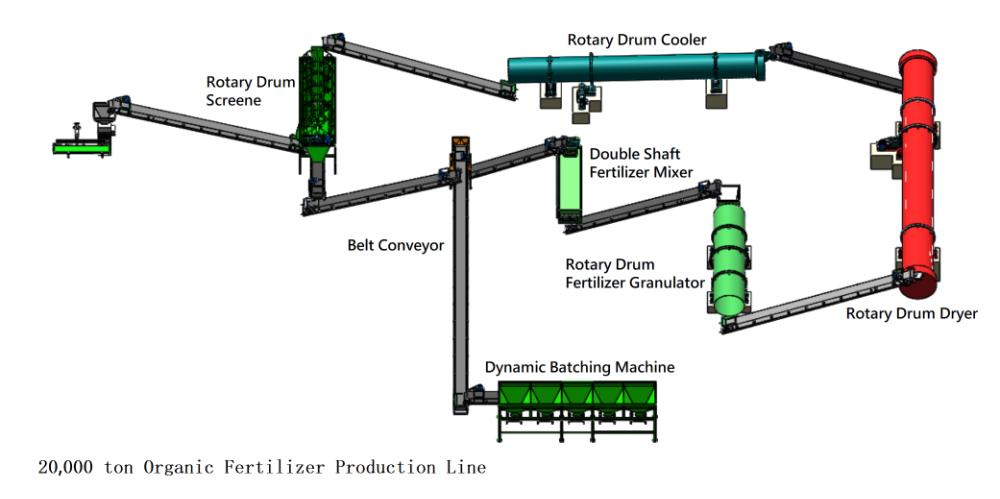

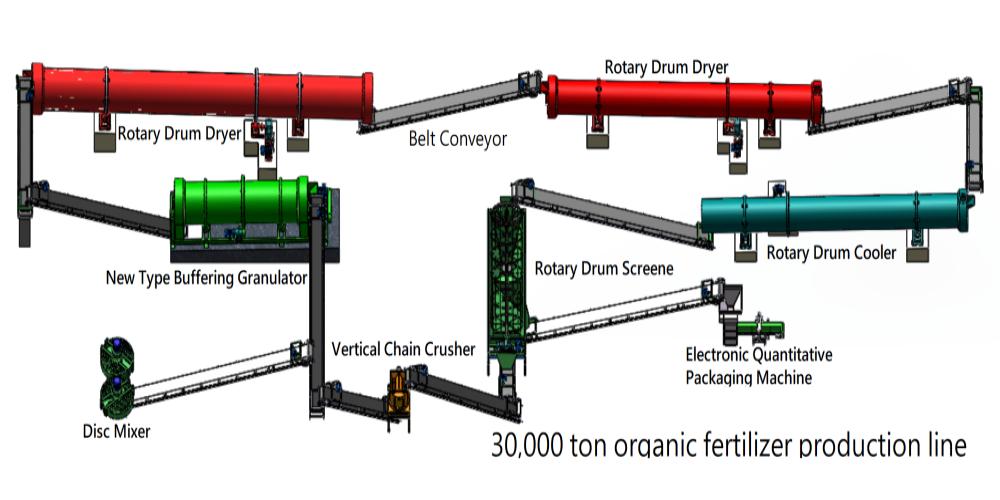

A fertilizer production line typically involves several processes that convert raw materials into usable fertilizers. The specific processes involved will depend on the type of fertilizer being produced, but some of the common processes include:

1.Raw Material Handling: The first step in fertilizer production is to handle the raw materials that will be used to make the fertilizer. This includes sorting and 2.cleaning the raw materials, as well as preparing them for the subsequent production processes.

3.Mixing and Crushing: The raw materials are then mixed and crushed to ensure uniformity of the mixture. This is important to ensure that the final product has consistent nutrient content.

4.Granulation: The mixed and crushed raw materials are then formed into granules using a granulation machine. Granulation is important to ensure that the fertilizer is easy to handle and apply, and that it releases its nutrients slowly over time.

5.Drying: The newly formed granules are then dried to remove any moisture that may have been introduced during the granulation process. This is important to ensure that the granules do not clump together or degrade during storage.

6.Cooling: The dried granules are then cooled to ensure that they are at a stable temperature before they are packaged and shipped.

7.Packaging: The final step in fertilizer production is to package the granules into bags or other containers, ready for distribution and sale.

Overall, fertilizer production lines are complex processes that require careful attention to detail and strict quality control measures to ensure that the final product is effective and safe to use.