Fertilizer production line

A fertilizer production line is a comprehensive system designed to efficiently manufacture various types of fertilizers for agricultural use. It involves a series of processes that transform raw materials into high-quality fertilizers, ensuring the availability of essential nutrients for plant growth and maximizing crop yields.

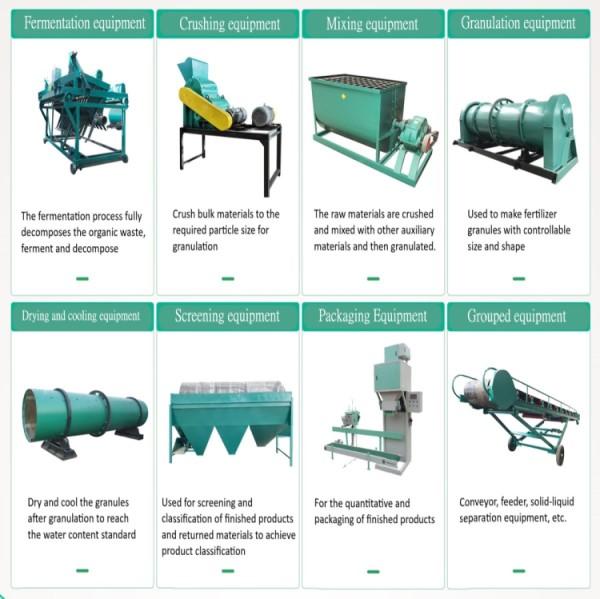

Components of a Fertilizer Production Line:

Raw Material Handling: The production line starts with the handling and preparation of raw materials, which can include organic waste, animal manure, crop residues, and mineral resources. These materials are carefully collected, sorted, and stored for further processing.

Crushing and Grinding: The raw materials undergo crushing and grinding processes to reduce their size and improve their solubility. This step increases the surface area of the materials, facilitating the subsequent chemical reactions and nutrient release.

Mixing and Blending: In the mixing and blending stage, the crushed materials are thoroughly mixed to achieve a balanced nutrient composition. This ensures that the resulting fertilizer provides a well-rounded supply of essential nutrients required for plant growth, such as nitrogen (N), phosphorus (P), and potassium (K).

Granulation: Granulation is a critical process in fertilizer production that converts the mixed materials into granules. This improves the handling and storage properties of the fertilizers and allows for controlled nutrient release in the soil. Various granulation techniques, including rotary drum granulation and extrusion granulation, are employed to form uniform-sized granules.

Drying and Cooling: After granulation, the fertilizer granules are dried to remove excess moisture, making them suitable for storage and packaging. Subsequently, a cooling process helps lower the temperature of the granules, preventing them from clumping together and maintaining their physical integrity.

Screening and Coating: The dried and cooled fertilizer granules undergo screening to remove oversized or undersized particles, ensuring uniformity in size. Additionally, some fertilizers may undergo a coating process, where a protective layer is applied to the granules to enhance their nutrient release characteristics and reduce nutrient loss.

Packaging and Storage: The final stage involves packaging the fertilizers into appropriate containers, such as bags or bulk storage. Proper packaging ensures convenient handling, transportation, and storage of the fertilizers, maintaining their quality until they are applied to the soil.

Benefits of a Fertilizer Production Line:

Nutrient Precision: A fertilizer production line allows for precise control over the nutrient composition of fertilizers. This ensures that crops receive the optimal balance of nutrients for their specific growth requirements, resulting in improved nutrient efficiency and reduced nutrient wastage.

Customization: The production line can be tailored to produce various types of fertilizers, including organic fertilizers, compound fertilizers, and specialty fertilizers. This versatility allows farmers and agricultural businesses to meet the specific nutritional needs of different crops and soil conditions.

Increased Crop Yields: The use of high-quality fertilizers produced by a fertilizer production line promotes healthy plant growth, leading to increased crop yields. The balanced nutrient content, controlled-release formulations, and improved nutrient availability contribute to enhanced plant vigor, productivity, and overall crop performance.

Environmental Sustainability: Fertilizer production lines can incorporate eco-friendly practices, such as utilizing organic waste as raw materials and implementing advanced technologies to minimize resource consumption and reduce emissions. This contributes to sustainable agriculture practices, waste management, and environmental conservation.

A fertilizer production line is a comprehensive system that efficiently transforms raw materials into high-quality fertilizers, providing essential nutrients for plant growth and maximizing crop yields. With its various stages, including raw material handling, crushing and grinding, mixing and blending, granulation, drying and cooling, screening and coating, and packaging and storage, a fertilizer production line ensures nutrient precision, customization, increased crop yields, and environmental sustainability.