Fertilizer manufacturing equipment

Fertilizer manufacturing equipment plays a crucial role in the production of high-quality fertilizers for agriculture and gardening. These specialized machines and systems are designed to efficiently process raw materials and convert them into nutrient-rich fertilizers that promote plant growth and enhance crop yields.

Importance of Fertilizer Manufacturing Equipment:

Fertilizer manufacturing equipment is essential for producing fertilizers that provide the necessary nutrients for plants. These machines enable the processing and transformation of raw materials, ensuring the optimal nutrient composition and physical characteristics of the final fertilizers. By utilizing advanced equipment, fertilizer manufacturers can meet the growing demand for high-quality fertilizers and contribute to sustainable agriculture practices.

Types of Fertilizer Manufacturing Equipment:

Fertilizer Blenders:

Fertilizer blenders are used to mix different raw materials and additives, ensuring a homogeneous blend with consistent nutrient content. These machines facilitate precise control over the fertilizer formulation, allowing manufacturers to customize the nutrient ratios according to specific crop requirements.

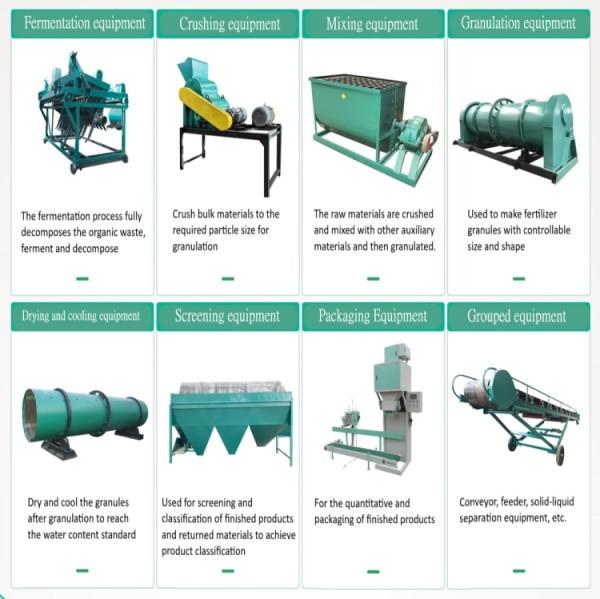

Granulation Equipment:

Granulation equipment is employed to convert the blended fertilizer mixture into granules. This process enhances the handling, storage, and application properties of the fertilizer. Various techniques, such as rotary drum granulators, pan granulators, and extrusion granulators, can be used to form uniform granules of different sizes.

Drying and Cooling Systems:

Drying and cooling systems are utilized to remove excess moisture from the granulated fertilizer and cool it to a suitable temperature for storage and packaging. These systems ensure the stability and longevity of the fertilizers by preventing moisture-related issues and maintaining their physical integrity.

Screening and Classification Equipment:

Screening and classification equipment is employed to separate oversized and undersized particles from the granulated fertilizers. This process ensures a uniform particle size distribution, enhancing the flowability and consistency of the final product.

Coating and Enrobing Machines:

Coating and enrobing machines are used to apply protective coatings or additives to the fertilizer granules. This enhances their nutrient release characteristics, reduces nutrient loss, and improves the efficiency of nutrient uptake by plants.

Applications of Fertilizer Manufacturing Equipment:

Agriculture and Crop Production:

Fertilizer manufacturing equipment is extensively used in the agricultural sector to produce fertilizers that supply essential nutrients for crop growth. These fertilizers enhance soil fertility, improve plant health, and increase crop yields by addressing nutrient deficiencies.

Gardening and Horticulture:

In gardening and horticulture, fertilizer manufacturing equipment enables the production of fertilizers tailored to specific plant needs. These fertilizers provide the necessary nutrients for healthy growth and vibrant blooms, contributing to successful gardening and landscaping projects.

Commercial Fertilizer Production:

Fertilizer manufacturing equipment is essential for commercial fertilizer production, catering to the needs of large-scale agriculture operations, greenhouse cultivation, and landscaping companies. These machines ensure efficient and consistent production of high-quality fertilizers to meet the demands of the market.

Custom Fertilizer Blending:

Fertilizer blending equipment allows for custom formulation of fertilizers based on soil analysis, crop requirements, and specific nutrient deficiencies. This enables the production of tailored fertilizers that address specific nutrient imbalances and maximize crop productivity.

Fertilizer manufacturing equipment plays a vital role in the production of high-quality fertilizers that support sustainable agriculture and plant growth. With various types of equipment available, including blenders, granulation systems, drying and cooling machines, screening equipment, and coating machines, manufacturers can efficiently process raw materials and create customized fertilizers with precise nutrient content and physical characteristics.