Fertilizer drying and cooling equipment

Fertilizer drying and cooling equipment are used to reduce the moisture content of the fertilizer granules and cool them down to an ambient temperature before storage or packaging.

Drying equipment usually employs hot air to reduce the moisture content of the fertilizer granules. There are various types of drying equipment available, including rotary drum dryers, fluidized bed dryers, and belt dryers.

Cooling equipment, on the other hand, utilizes cold air or water to cool down the fertilizer granules. This is necessary because the high temperature from the drying process can damage the granules if not properly cooled. Cooling equipment includes rotary drum coolers, fluidized bed coolers, and counterflow coolers.

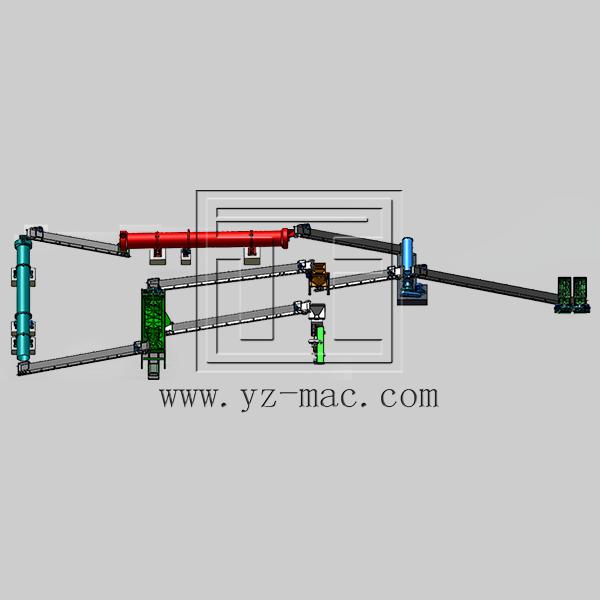

Many modern fertilizer production plants integrate drying and cooling into a single piece of equipment, known as a rotary drum dryer-cooler. This can reduce the overall equipment footprint and improve efficiency.