Fertilizer blenders

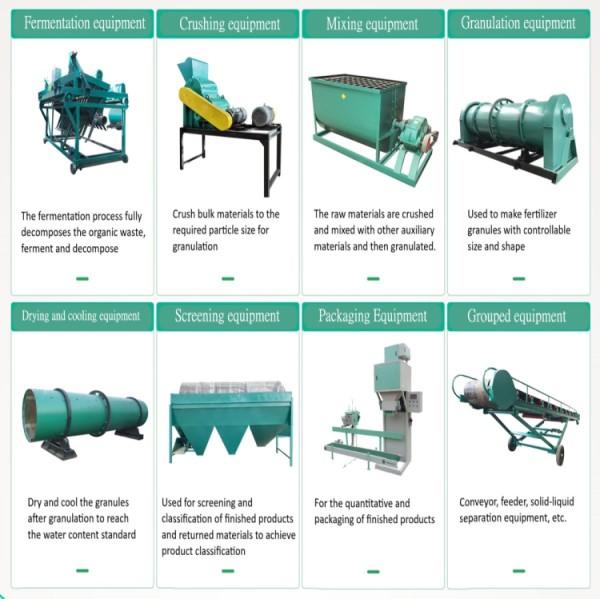

Fertilizer blenders, also known as fertilizer mixing machines, are specialized equipment designed to blend various fertilizer components into a homogeneous mixture. These machines play a crucial role in the fertilizer production process by ensuring the precise and uniform distribution of nutrients in fertilizers.

Benefits of Fertilizer Blenders:

Uniform Nutrient Distribution: Fertilizer blenders ensure the even distribution of nutrients throughout the fertilizer mixture. This uniformity guarantees that each granule or particle of fertilizer contains the required amount of nutrients, allowing for consistent nutrient availability to plants during application.

Customizable Formulations: Fertilizer blenders offer the flexibility to create custom fertilizer formulations by blending different fertilizer components, such as nitrogen, phosphorus, potassium, and micronutrients. This enables the production of fertilizers tailored to specific crop requirements, soil conditions, and growth stages.

Enhanced Nutrient Efficiency: The precise blending achieved by fertilizer blenders promotes optimal nutrient utilization by plants. The uniform distribution of nutrients in the fertilizer mixture ensures that plants can access the required nutrients evenly, reducing the risk of nutrient imbalances and maximizing nutrient uptake efficiency.

Time and Labor Savings: Fertilizer blenders automate the mixing process, reducing the time and labor required for manual blending. These machines can handle large volumes of fertilizer components, resulting in increased productivity and cost savings for fertilizer manufacturers and blenders.

Working Principle of Fertilizer Blenders:

Fertilizer blenders typically consist of a blending chamber or drum equipped with rotating blades or paddles. The fertilizer components are loaded into the chamber, and as the blades rotate, the materials are mixed and blended thoroughly. The blending time and speed can be adjusted to achieve the desired level of mixing and homogeneity. The blended fertilizer mixture is then discharged for packaging or further processing.

Applications of Fertilizer Blenders:

Fertilizer Production Facilities: Fertilizer blenders are extensively used in fertilizer production facilities to mix and blend various fertilizer components, additives, and micronutrients. These machines ensure the precise formulation and consistent quality of fertilizers for commercial distribution.

Agricultural and Horticultural Operations: Fertilizer blenders find applications in agriculture and horticulture, where custom fertilizer formulations are required. They allow farmers, landscapers, and gardeners to create fertilizers tailored to specific crop needs, soil conditions, and growth stages, ensuring optimal nutrient supply for healthy plant growth.

Soil Amendment and Remediation: Fertilizer blenders can be used to blend soil amendments, such as organic matter, compost, and lime, with fertilizers. This promotes soil health, improves nutrient availability, and aids in soil remediation efforts, helping to restore and revitalize degraded soils.

Custom Blending Services: Some companies specialize in custom blending services, where they mix fertilizers according to customer specifications. Fertilizer blenders play a critical role in these operations by ensuring accurate blending and consistent quality control.

Fertilizer blenders are essential machines in the fertilizer industry, enabling the precise blending of fertilizer components to create uniform and customized fertilizer formulations. The benefits of using fertilizer blenders include uniform nutrient distribution, customizable formulations, enhanced nutrient efficiency, and time and labor savings. Fertilizer blenders find applications in fertilizer production facilities, agricultural and horticultural operations, soil amendment and remediation, and custom blending services.