Fermentation Tank - China Manufacturers, Suppliers, Factory

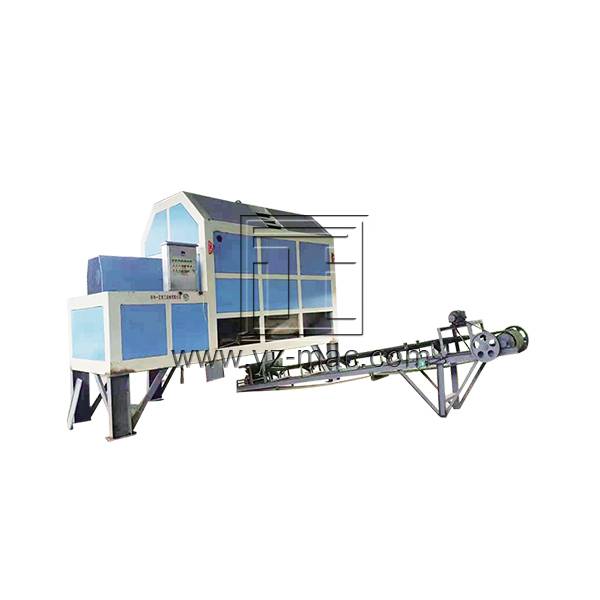

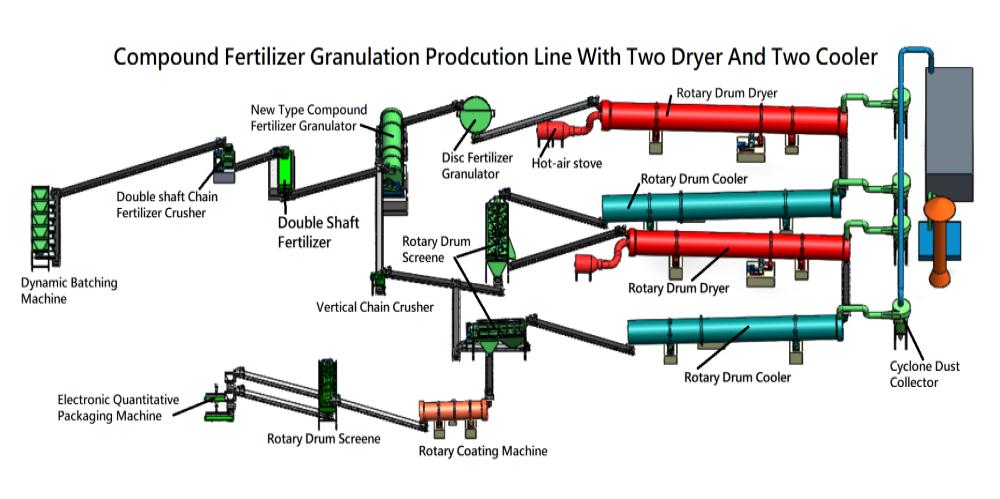

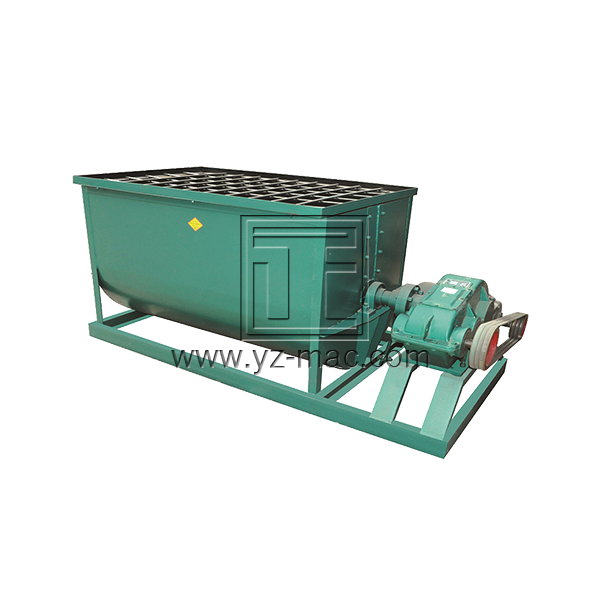

Compound fertilizer is a compound fertilizer that is mixed and batched according to different proportions of a single fertilizer, and a compound fertilizer containing two or more elements of nitrogen, phosphorus and potassium is synthesized through chemical reaction, and its nutrient content is uniform and the particle size is consistent. The raw materials for compound fertilizer production include urea, ammonium chloride, ammonium sulfate, liquid ammonia, monoammonium phosphate, diammonium phosphate, potassium chloride, potassium sulfate, including some fillers such as clay. In addition, organic materials such as various animal manures are added according to soil needs. Process flow of compound fertilizer production line: raw material batching→raw material mixing→granulation→drying→cooling→finished product screening→return particle crushing→coating→finished product packaging→storage. Fermentation Tank, 25 Ton/H Feed Pellet Cooler Machine, Double Shaft Fertilizer Mixer, Hydraulic Lifing Comost Turner,Feed Pellets Cooling Machine. In simple terms, compost is the breaking down of fecal organic matter that can be used to help plants grow and keep soil healthy. Manure compost is a valuable soil amendment that increases the nutrients needed for plant growth and development. The product will supply to all over the world, such as Europe, America, Australia,Qatar, Algeria,Czech republic, Frankfurt.Organic fertilizer granulation machine

Related Products