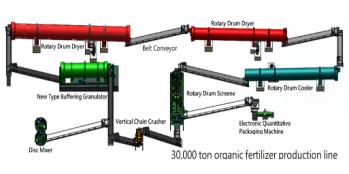

Equipment for producing duck manure fertilizer

Equipment for producing duck manure fertilizer is similar to other livestock manure fertilizer production equipment. It includes:

1.Duck manure treatment equipment: This includes solid-liquid separator, dewatering machine, and compost turner. The solid-liquid separator is used to separate solid duck manure from the liquid portion, while the dewatering machine is used to further remove moisture from the solid manure. The compost turner is used to mix the solid manure with other organic materials to create a suitable environment for composting.

2.Fermentation equipment: This includes a fermentation tank or composting bin, which is used to facilitate the decomposition of organic matter in the compost pile.

3.Granulation equipment: This includes a fertilizer granulator, which is used to shape the composted material into granules that are easy to handle and apply.

4.Drying and cooling equipment: This includes a rotary dryer and cooler, which are used to remove excess moisture from the granules and cool them down to a suitable temperature for storage.

5.Screening equipment: This includes a vibrating screen, which is used to separate oversized and undersized granules from the finished product.

6.Conveying equipment: This includes a belt conveyor or bucket elevator, which is used to transport the finished product to storage or packaging.

7.Supporting equipment: This includes a dust collector, which is used to collect and remove dust generated during the production process.