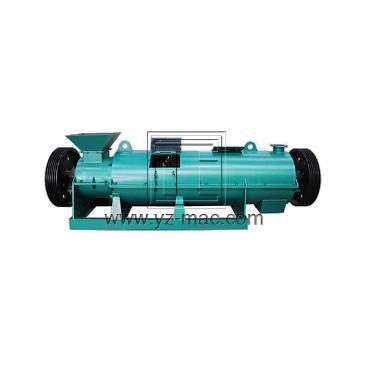

Dynamic automatic batching machine

A dynamic automatic batching machine is a type of industrial equipment used to automatically measure and mix different materials or components in precise quantities. The machine is commonly used in the manufacturing of products such as fertilizers, animal feed, and other granular or powder-based products.

The batching machine consists of a series of hoppers or bins that hold the individual materials or components to be mixed. Each hopper or bin is equipped with a measuring device, such as a load cell or weigh belt, that accurately measures the amount of material being added to the mix.

The machine is designed to be fully automated, with a programmable logic controller (PLC) controlling the sequence and timing of each ingredient addition. The PLC can be programmed to control the flow rate of each material, as well as the overall mix time and other parameters.

One of the advantages of using a dynamic automatic batching machine is that it can improve production efficiency and accuracy, while reducing labor costs. The machine can mix and dispense precise quantities of ingredients at high speeds, which can help to increase production output and reduce waste.

Additionally, the machine can be equipped with features such as automatic cleaning systems and data logging capabilities, which can help to improve process control and quality assurance. The machine can also be integrated with other production equipment, such as bagging machines or conveyors, to create a fully automated production line.

However, there are also some potential drawbacks to using a dynamic automatic batching machine. For example, the machine may require significant initial investment and ongoing maintenance costs. Additionally, the machine may require specialized training and expertise to operate and maintain, which can add to the overall cost of operation. Finally, the machine may be limited in its ability to handle certain types of materials or components, which can impact its usefulness in certain production applications.