Dry powder granulator

A dry powder granulator, also known as a dry granulation machine, is a specialized equipment used to transform dry powders into granules. This process enhances the flowability, stability, and usability of the powders, making them easier to handle, transport, and store.

Importance of Dry Powder Granulation:

Dry powder granulation offers numerous benefits for both manufacturers and end-users. It transforms fine powders into granules, which possess improved flowability, reduced dustiness, and enhanced physical and chemical stability. The granules are easier to handle, accurately dose, and mix with other materials. This makes dry powder granulation a critical step in industries where powder processing and handling are involved, such as pharmaceuticals, food, chemicals, and cosmetics.

Working Principle of Dry Powder Granulators:

Dry powder granulators typically utilize compaction or agglomeration processes to transform powders into granules.

Compaction: In this process, the dry powder is compressed using rollers or presses to form compacted sheets or ribbons. These sheets or ribbons are then broken down into smaller granules using milling or sizing equipment. Compaction is suitable for materials that possess cohesive properties, allowing them to bind together under pressure.

Agglomeration: Agglomeration involves the formation of granules by bringing together dry powders through the use of binders, heat, or pressure. The powders are mixed with a liquid binder to form granules, which are then dried to remove moisture. Agglomeration is suitable for materials that do not possess natural cohesive properties.

Applications of Dry Powder Granulators:

Pharmaceuticals: Dry powder granulation is widely used in the pharmaceutical industry to produce granules for tablet manufacturing. The granules improve flowability, enhance drug uniformity, and facilitate accurate dosing during tablet compression. Dry powder granulation is commonly employed in the production of immediate-release tablets, controlled-release formulations, and oral solid dosage forms.

Food and Beverage: Dry powder granulation finds applications in the food and beverage industry. It is used to produce granules for instant beverages, seasoning blends, nutritional supplements, and powdered food formulations. The granules improve solubility, dispersibility, and handling characteristics, enhancing the quality and convenience of the final food products.

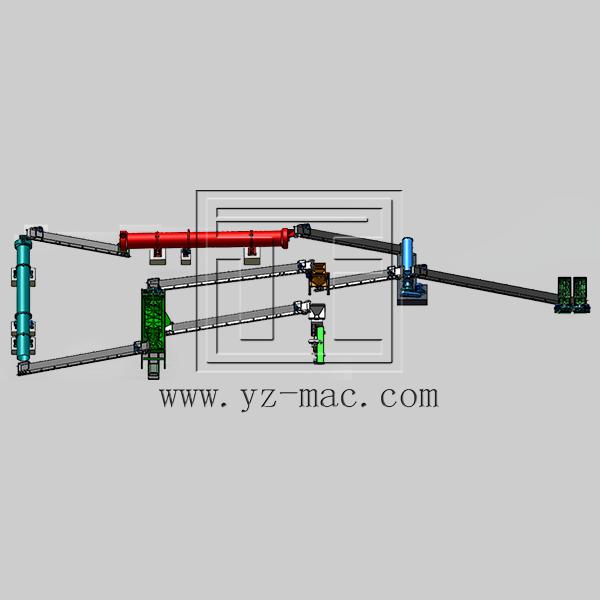

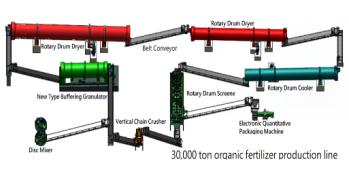

Chemicals: Dry powder granulation is utilized in the chemical industry to transform powders into granules for various applications. It is commonly employed in the production of fertilizers, detergents, catalysts, and specialty chemicals. The granules offer improved handling, reduced dust generation, and enhanced storage stability.

Cosmetics and Personal Care: Dry powder granulation plays a role in the production of cosmetic and personal care products. It is used to produce granules for powders, pressed powders, blushes, and eyeshadows. The granules provide better adhesion, smoother application, and improved sensory properties.

Dry powder granulation is a vital process that transforms powders into granules, offering improved flowability, stability, and usability. By utilizing compaction or agglomeration processes, dry powder granulators enhance the handling, dosing, and mixing characteristics of powders in industries such as pharmaceuticals, food, chemicals, and cosmetics. The applications of dry powder granulators range from tablet manufacturing in pharmaceuticals to the production of instant beverages, fertilizers, and cosmetics. With their ability to transform powders into granules, dry powder granulators contribute to the efficiency, convenience, and quality of various products in multiple industries.