Dry granulation machine

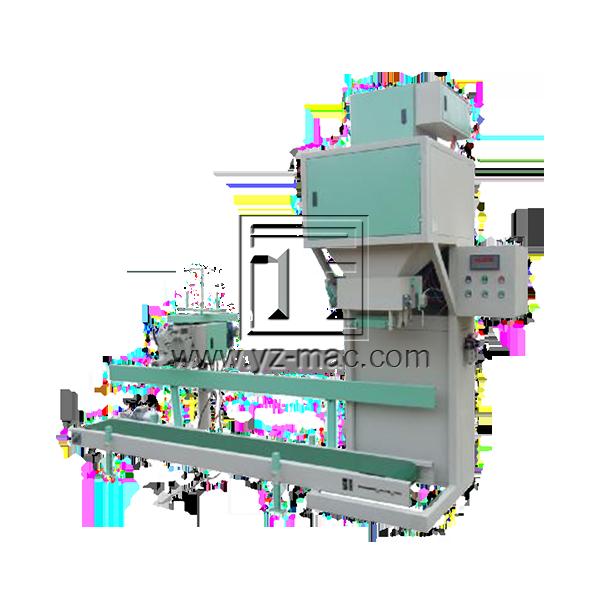

A dry granulation machine, also known as a dry granulator or dry compactor, is a specialized equipment designed to convert powdered or granular materials into solid granules without the use of liquids or solvents. This process involves compacting the materials under high pressure to create uniform, free-flowing granules.

Benefits of Dry Granulation:

Preserves Material Integrity: Dry granulation preserves the chemical and physical properties of the materials being processed since no heat or moisture is involved. This is especially beneficial for heat-sensitive or moisture-sensitive materials that may undergo degradation or alteration in wet granulation processes.

Improved Granule Quality: Dry granulation produces granules with a uniform particle size distribution, density, and hardness. This results in improved flow properties, reduced segregation, and enhanced compressibility of the granules. The uniformity and strength of the granules contribute to better product performance and process efficiency.

Cost and Time Savings: Dry granulation eliminates the need for drying processes, as no liquid binders or solvents are used. This significantly reduces energy consumption, processing time, and production costs compared to wet granulation methods.

Environmental Friendliness: Dry granulation is a more environmentally friendly process since it does not involve the use of water or solvents that may generate wastewater or require additional treatment. It also reduces the overall carbon footprint of the production process.

Working Principle of Dry Granulation Machines:

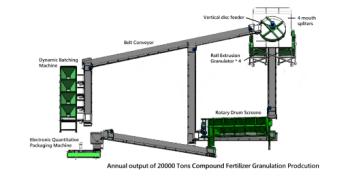

Dry granulation machines typically consist of a pair of counter-rotating rolls or a rotary drum. The material to be granulated is fed into the gap between the rolls or into the drum. Under high pressure, the material is compacted and forced through the gap, forming densified flakes. These flakes are then broken into granules of the desired size using a granulating screen or milling process.

Applications of Dry Granulation Machines:

Pharmaceutical Industry: Dry granulation machines are widely used in the pharmaceutical industry for the production of tablets and capsules. They can process a variety of materials, including active pharmaceutical ingredients (APIs), excipients, and dry blends, to produce uniform and free-flowing granules suitable for direct compression or encapsulation.

Chemical Industry: Dry granulation machines find applications in the chemical industry for the granulation of powders, such as fertilizers, pigments, catalysts, and specialty chemicals. The resulting granules offer improved handling, reduced dust generation, and enhanced flowability for easier storage, transportation, and subsequent processing.

Food and Nutraceutical Industry: Dry granulation machines are utilized in the food and nutraceutical industry for the granulation of powdered ingredients, such as vitamins, minerals, additives, and flavorings. The resulting granules enable better blending, controlled release, and improved dispersibility in food and dietary supplement formulations.

Recycling and Waste Management: Dry granulation machines play a role in recycling and waste management processes. They can compact and granulate materials such as plastic flakes, rubber crumbs, and metal powders, facilitating their storage, transport, and further processing for recycling or waste utilization.

Dry granulation machines offer numerous benefits, including the preservation of material integrity, improved granule quality, cost and time savings, and environmental friendliness. By compacting and granulating materials without the use of liquids, these machines provide uniform, free-flowing granules suitable for various applications in pharmaceuticals, chemicals, food, nutraceuticals, and recycling industries. Investing in a dry granulation machine allows for efficient and reliable granulation processes, resulting in enhanced product performance, process efficiency, and sustainability in material processing and manufacturing.