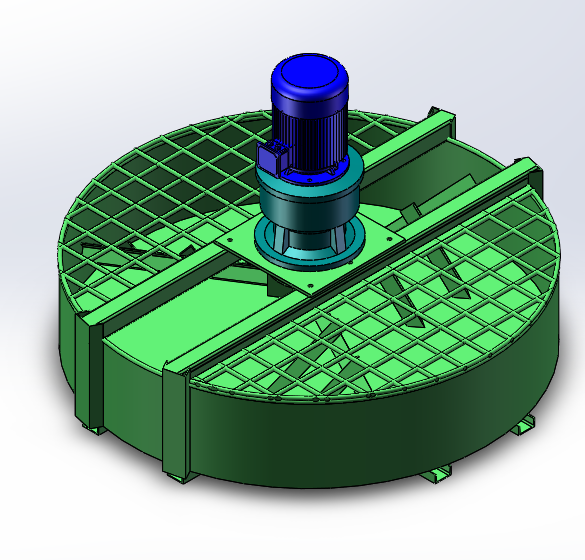

Disc Mixer Machine

The Disc Fertilizer Mixer Machine mixes the raw material, consisting of a mixing disc, a mixing arm, a frame, a gearbox package and a transmission mechanism. Its characteristics are that there is a cylinder arranged in the center of the mixing disk, a cylinder cover is arranged on the drum, and the mixing arm is firmly connected to the cylinder cover. One end of the stirring shaft connects to the cylinder cover passes through the cylinder, and the stirring shaft is driven. The cylinder cover rotates, thus driving the stirring arm to rotate, and the transmission mechanism that drives the stirring shaft from the four-stage transmission mechanism.

|

Model |

Stir machine |

Turn speed |

Power |

Production capacity |

Outer ruler inch L × W × H |

Weight |

|

|

Diameter |

Wall height |

||||||

|

|

mm |

mm |

r/min |

kw |

t/h |

mm |

kg |

|

YZJBPS-1600 |

1600 |

400 |

12 |

5.5 |

3-5 |

1612×1612×1368 |

1200 |

|

YZJBPS-1800 |

1800 |

400 |

10.5 |

7.5 |

4-6 |

1900×1812×1368 |

1400 |

|

YZJBPS-2200 |

2200 |

500 |

10.5 |

11 |

6-10 |

2300×2216×1503 |

1668 |

|

YZJBPS-2500 |

2500 |

550 |

9 |

15 |

10-16 |

2600×2516×1653 |

2050 |

Disc/ Pan Fertilizer Mixer Machine is mainly used to produce mixtures of fertilizer raw materials. The mixer stirs evenly by rotating and the mixed materials will be transferred directly from the conveying equipment to the next production process.

The Disc Fertilizer Mixer Machine can mix all the raw materials in the mixer to achieve evenly and thoroughly mixing materials. It can also be used as mixing and feeding equipment in the whole fertilizer production line.

The main Disc Fertilizer Mixer Machine body is lined with polypropylene board or stainless steel material, so it is not easy to stick and wear resistant. The cycloid needle wheel reducer has the characteristics of compact structure, easy operation, uniform stirring, and convenient discharge.

(1) long service life, energy saving and power saving.

(2) Small size and fast stirring speed.

(3) Continuous discharge to meet the continuous production requirements of the entire production line.

|

mm |

mm |

r/min |

kw |

t/h |

mm |

kg |

|

|

YZJBPS-1600 |

1600 |

400 |

12 |

5.5 |

3-5 |

1612×1612×1368 |

1200 |

|

YZJBPS-1800 |

1800 |

400 |

10.5 |

7.5 |

4-6 |

1900×1812×1368 |

1400 |

|

YZJBPS-2200 |

2200 |

500 |

10.5 |

11 |

6-10 |

2300×2216×1503 |

1668 |

|

YZJBPS-2500 |

2500 |

550 |

9 |

15 |

10-16 |

2600×2516×1653 |

2050 |