Disc granulator production line

A disc granulator production line is a type of fertilizer production line that uses a disc granulator machine to produce granular fertilizer products. The disc granulator is a kind of equipment that creates granules by rotating a large disc, which has a number of inclined and adjustable angle pans attached to it. The pans on the disc rotate and move the material to create granules.

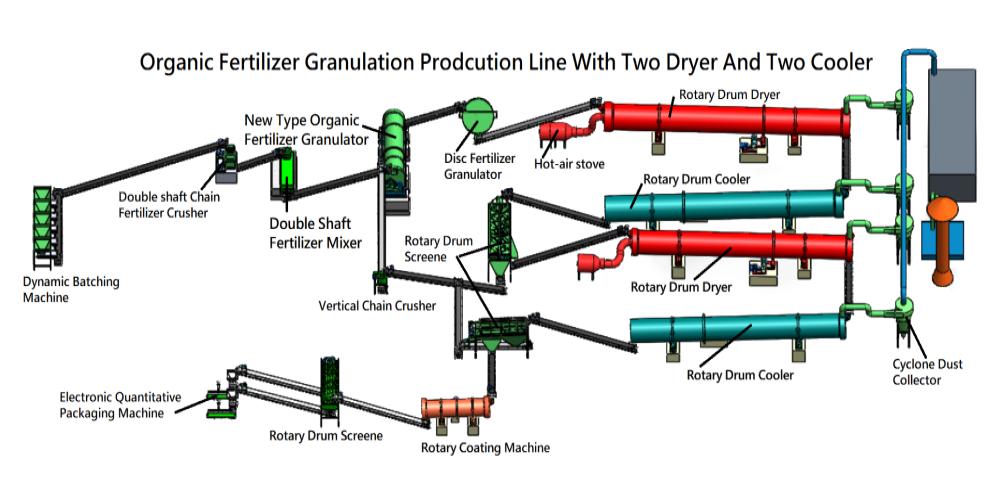

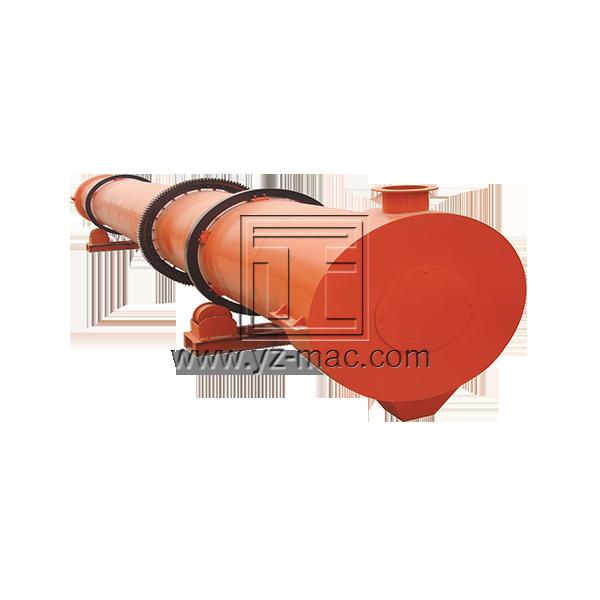

The disc granulator production line typically includes a series of equipment, such as a compost turner, crusher, mixer, disc granulator machine, dryer, cooler, screening machine, and packing machine.

The process starts with the collection of raw materials, which can include animal manure, crop residues, food waste, and other organic materials. The raw materials are then crushed and mixed with other ingredients such as nitrogen, phosphorus, and potassium to create a balanced fertilizer mixture.

The mixture is then fed into the disc granulator, which rotates and creates the granules by using the pans attached to the disc. The resulting granules are then dried and cooled to reduce the moisture content and ensure they are stable for storage.

Finally, the granules are screened to remove any oversized or undersized particles, and then the finished products are packed into bags or containers for distribution and sale.

Overall, the disc granulator production line is an efficient and cost-effective way to produce high-quality granular fertilizer products for agricultural use.