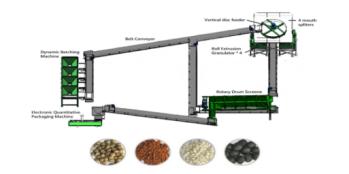

Cow manure fertilizer granulation equipment

Cow manure fertilizer granulation equipment is used to turn fermented cow manure into compact, easy-to-store granules. The process of granulation helps to improve the physical and chemical properties of the fertilizer, making it easier to apply and more effective at delivering nutrients to plants.

The main types of cow manure fertilizer granulation equipment include:

1.Disc granulators: In this type of equipment, the fermented cow manure is fed onto a rotating disc that has a series of angled scoops or “paddles.” As the disc rotates, the manure is thrown against the paddles, which cause it to break up and form small granules. The granules are then dried and screened to remove any fines or oversized particles.

2.Rotary drum granulators: In this type of equipment, the fermented cow manure is fed into a large, rotating drum. As the drum rotates, a series of fins inside the drum lift and drop the manure, causing it to tumble and roll into small, round granules. The granules are then dried and screened to remove any fines or oversized particles.

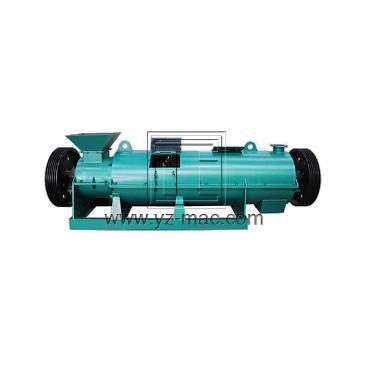

3.Double roller extrusion granulators: In this type of equipment, the fermented cow manure is forced through two rotating rollers that press and compact the material into small, dense granules. The granules are then dried and screened to remove any fines or oversized particles.

The use of cow manure fertilizer granulation equipment can help to improve the efficiency and effectiveness of fertilization in agriculture. The specific type of equipment used will depend on factors such as the desired size and shape of the granules, the production capacity, and the available resources.