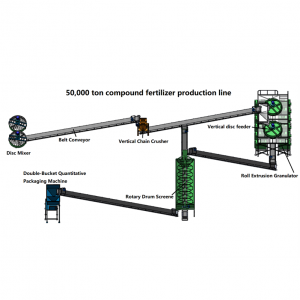

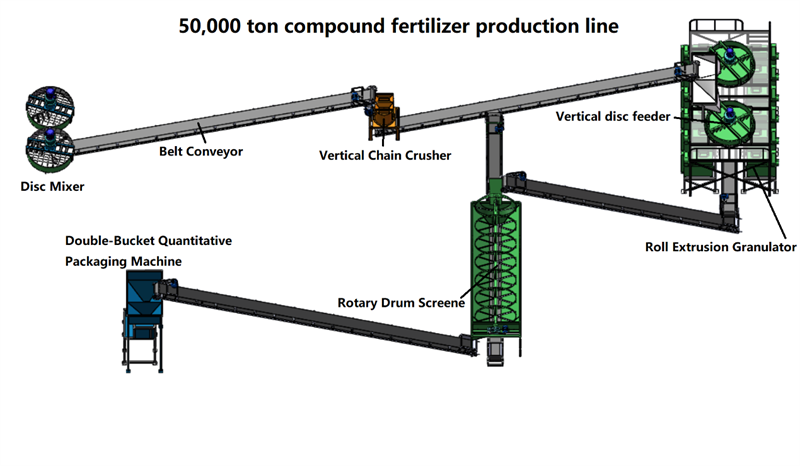

Compound fertilizer production line with an annual output of 50,000 tons

compound fertilizer production line with an annual output of 50,000 tons factory direct ex-factory price, Yizheng Heavy Industry provides a full set of organic fertilizer production line construction plan consultation free of charge. It can provide a complete set of organic fertilizer equipment, organic fertilizer granulator equipment, organic fertilizer turning machine, fertilizer processing equipment and other complete production equipment.

The compound fertilizer production line with an annual output of 50,000 tons can be used to produce high, medium and low concentrated compound fertilizers with various compound raw materials. Compound fertilizers with different concentrations and different formulas can be formulated according to actual needs to effectively supplement the nutrients needed by crops and solve the contradiction between crop demand and soil supply. Compound fertilizer refers to fertilizer containing any two or three nutrients of crop nutrient elements nitrogen, phosphorus and potassium synthesized by chemical reaction or mixing method; compound fertilizer can be powder or granular.

Work Principle :

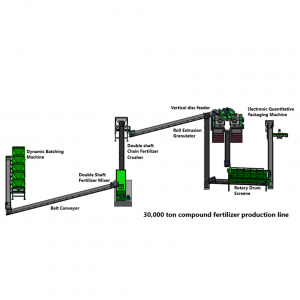

The process flow of the composite fertilizer production line can usually be divided into: raw material ingredients, mixing, crushing of nodules, granulation, initial screening, particle drying, particle cooling, secondary screening, finished particle coating, and quantitative packaging of finished products.

1. Raw material ingredients:

According to market demand and local soil determination results, urea, ammonium nitrate, ammonium chloride, ammonium thiophosphate, ammonium phosphate, diammonium phosphate, heavy calcium, potassium chloride (potassium sulfate) and other raw materials are distributed in a certain proportion. Additives, trace elements, etc. are used as ingredients in a certain proportion through belt scales. According to the formula ratio, all raw material ingredients are evenly flowed from belts to mixers, a process called premixes. It ensures the accuracy of the formulation and achieves efficient continuous ingredients.

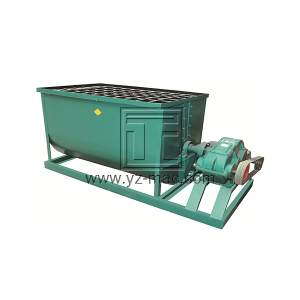

2. Mix:

The prepared raw materials are fully mixed and stirred evenly, laying the foundation for high-efficiency and high-quality granular fertilizer. A horizontal mixer or disk mixer can be used for uniform mixing and stirring.

3. Crush:

The lumps in the material are crushed after mixing evenly, which is convenient for subsequent granulation processing, mainly using chain crusher.

4. Granulation:

The material after mixing evenly and crushed is transported to the granulation machine through a belt conveyor, which is the core part of the composite fertilizer production line. The choice of granulator is very important. Our factory produces disk granulator, drum granulator, roller extruder or compound fertilizer granulator.

5. Screening:

The particles are sieved, and the unqualified particles are returned to the upper mixing and stirring link for reprocessing. Generally, a roller sieve machine is used.

6. Packaging:

This process adopts an automatic quantitative packaging machine. The machine is composed of an automatic weighing machine, a conveyor system, a sealing machine, etc. You can also configure hoppers according to customer requirements. It can realize the quantitative packaging of bulk materials such as organic fertilizer and compound fertilizer, and has been widely used in food processing factories and industrial production lines.

For more detailed solutions or products, please pay attention to our official website:

https://www.yz-mac.com/50000-ton-compound-fertilizer-production-linev/