Compound fertilizer production line.

The non-drying extrusion granulation production line can produce high, medium and low concentration compound fertilizers for various crops. The production line does not require drying, has low investment and low energy consumption. The pressure rollers for non-drying extrusion granulation can be designed into different shapes and sizes so that they can be extruded to produce granules of different sizes and shapes.

Work Principle :

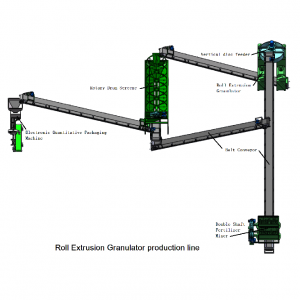

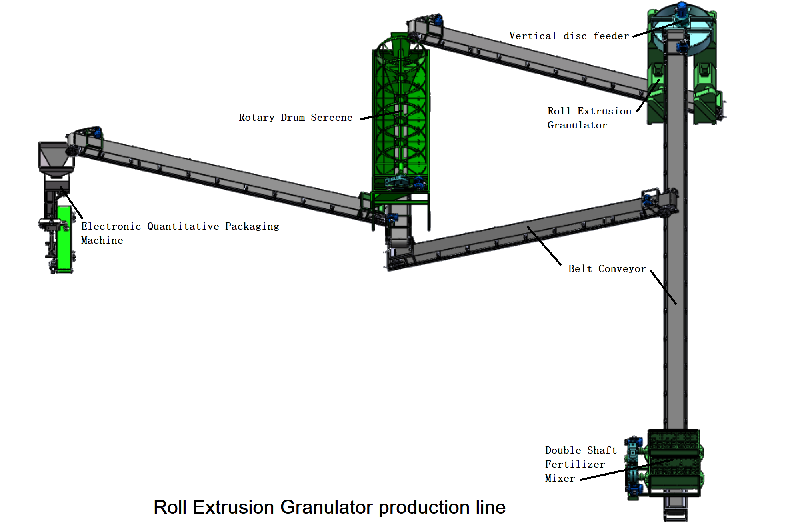

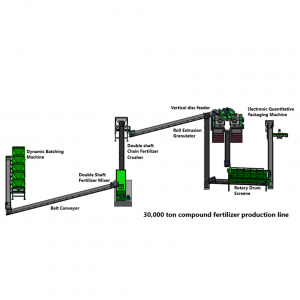

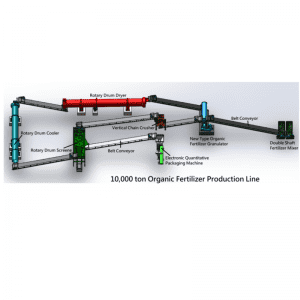

The dryless extrusion granulator includes automatic ingredients, belt conveyors, biaxial mixers, disc feeders, extrusion granulation machines, roller sieves, finished warehouses, automatic packaging machines, etc.

1. Dynamic Batching Machine

The automatic ingredients machine feed the raw materials according to each formula ratio, which can automatically complete the batching process with high accuracy and efficiency, so as to ensure the quality of fertilizer. After the ingredients, the material is transported to the double-axis blender.

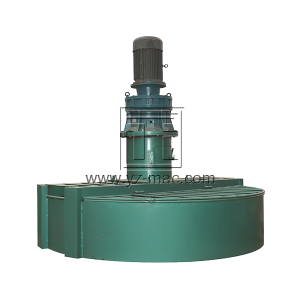

2. Double Shaft Fertilizer Mixer

The disc mixer uses a cycloid needle wheel reducer to drive the spindle, and then drive the stirring arm to rotate and stir. With the continuous flip and stirring of the blades on the mixing arm, the raw materials are fully mixed. The mixed material is excreted from the outlet at the bottom. The disk adopts polypropylene plate or stainless steel lining, which is not easy to stick and simple and practical.

3. Roller extrusion granulator

The mixed raw material is transported from the belt conveyor to the disc feeder, which evenly sends the material to the four roller extruder under the feeder through the hopper. The machine squeezes the material into pieces to the broken chamber under the roller through a reverse rotating high-voltage roller, and then separates the required particles as the double-axis wolf tooth rod rotates. The roller is made of a new corrosion-resistant, wear-resistant and impact-resistant alloy material.

4. Rotary Drum Screene

Extrified granulation particles are transported to the roller filter through a belt conveyor, and substandard particles flow out of the large particles outlet on the side through the screen hole, and then transported to the disc feeder for secondary granulation, and qualified particles are fed from the lower end outlet and transported to the finished area.

5. Electronic Quantitative Packaging

Through the hopper, qualified particles are weighed quantitatively, and then packaged by an automatic packaging machine.

The compound fertilizer production line is preferably Yizheng Heavy Industry, an enterprise specializing in the research and development, production and sales of organic fertilizer production equipment. Provide large, medium and small-scale organic fertilizer production equipment, compound fertilizer production equipment, reasonable prices and excellent quality.

For more detailed solutions or products, please pay attention to our official website:

https://www.yz-mac.com/npk-compound-fertilizer-extrusion-granulation-production-line/