Compound fertilizer production equipment

Compound fertilizer production equipment is used to manufacture compound fertilizers, which contain two or more essential plant nutrients such as nitrogen, phosphorus, and potassium. Compound fertilizers are produced by combining different raw materials and chemical substances to create a balanced nutrient blend that meets the specific needs of different crops and soils.

The main equipment used in compound fertilizer production includes:

1.Crushing Equipment: Used to crush and grind the raw materials into small particles. This process helps increase the surface area of the raw materials, making it easier to mix and granulate. Crushing equipment includes crushers, grinders, and shredders.

2.Mixing Equipment: Used to blend the different raw materials together to create a homogeneous mixture. This equipment includes horizontal mixers, vertical mixers, and disc mixers.

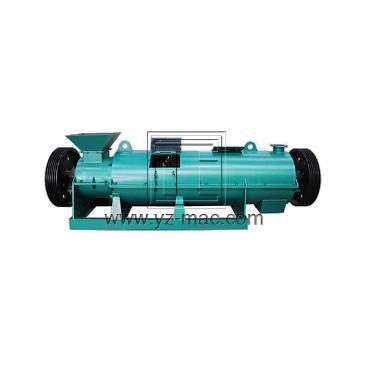

3.Granulating Equipment: Used to convert the mixed materials into granules or pellets. Granulating equipment includes rotary drum granulators, double roller extrusion granulators, and pan granulators.

4.Drying Equipment: Used to reduce the moisture content of the granules, making them easier to handle and store. Drying equipment includes rotary dryers, fluidized bed dryers, and belt dryers.

5.Cooling Equipment: Used to cool the granules after drying to prevent them from sticking together or breaking down. Cooling equipment includes rotary coolers, fluidized bed coolers, and counter-flow coolers.

6.Screening Equipment: Used to remove any oversized or undersized granules from the final product, ensuring that the product is of consistent size and quality. Screening equipment includes vibrating screens and rotary screens.

7.Packaging Equipment: Used to package the final product into bags or containers for storage and distribution. Packaging equipment includes automatic bagging machines, filling machines, and palletizers.

Compound fertilizer production equipment can be customized to suit different production capacities and requirements, depending on the specific needs of the user. The equipment is designed to produce high-quality, balanced fertilizers that provide consistent nutrient levels for crops, helping to increase yields and improve soil health.