Compound fertilizer machine

A compound fertilizer machine plays a crucial role in the production of compound fertilizers, which are blended fertilizers containing two or more essential nutrients. These machines provide efficient and precise nutrient blending, granulation, and packaging processes.

Types of Compound Fertilizer Machines:

Batch Mixers:

Batch mixers are commonly used in compound fertilizer production. They allow precise control over the blending process by combining solid materials, such as granular or powdered fertilizers, with liquid additives or micronutrients. Batch mixers ensure uniform distribution of nutrients throughout the fertilizer blend, resulting in a consistent and balanced product.

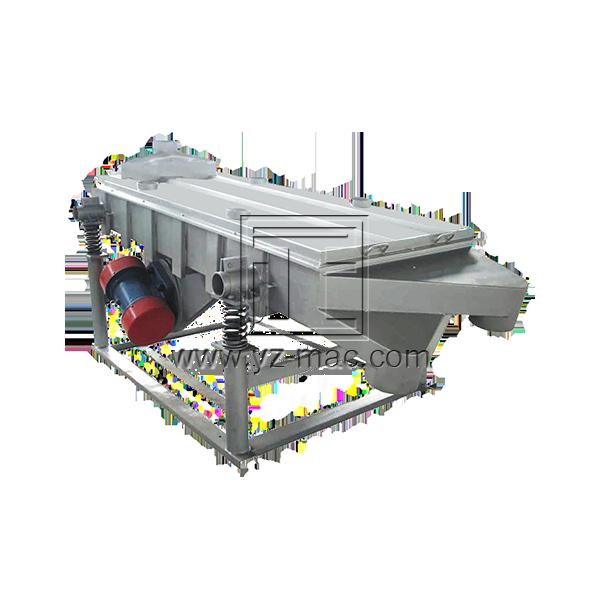

Granulation Machines:

Granulation machines are employed to transform the blended fertilizer materials into granules, which are easier to handle, transport, and apply. These machines use various techniques such as drum granulation, pan granulation, or extrusion to agglomerate the fertilizer particles and form uniform granules with controlled release properties.

Coating Machines:

Coating machines are used to apply a protective coating on the surface of compound fertilizer granules. This coating enhances the granules’ stability, improves nutrient release control, and protects against moisture and external factors. Coating machines ensure uniform coating distribution and facilitate the production of slow-release or controlled-release fertilizers.

Packaging Machines:

Packaging machines are responsible for efficiently packaging the final compound fertilizer products. These machines automate the weighing, filling, and sealing processes, ensuring accurate packaging and minimizing manual labor. Packaging machines can handle various packaging formats, including bags, sacks, or bulk containers, depending on the intended market and customer requirements.

Applications of Compound Fertilizer Machines:

Agriculture:

Compound fertilizer machines find extensive applications in conventional and precision agriculture. They enable the production of tailor-made compound fertilizers, customized to meet specific crop nutrient requirements. The precise blending, granulation, and coating processes ensure a balanced nutrient composition, enabling farmers to optimize fertilizer application, increase crop productivity, and minimize nutrient loss.

Horticulture:

In horticultural practices, such as greenhouse cultivation, nurseries, and ornamental plant production, compound fertilizer machines play a vital role. They help produce specialized compound fertilizers suitable for specific plant varieties, growth stages, or cultivation conditions. These fertilizers provide a precise balance of nutrients, promoting healthy plant growth, flowering, and fruit development.

Landscape and Turf Management:

Compound fertilizers produced using fertilizer machines are widely used in landscaping, turf management, and sports field maintenance. These fertilizers deliver a balanced nutrient supply essential for maintaining healthy lawns, green spaces, and athletic fields. The controlled-release or slow-release properties of some compound fertilizers ensure long-lasting nutrition, reducing the frequency of fertilizer applications.

Controlled-Environment Agriculture:

In controlled-environment agriculture systems like hydroponics, aeroponics, or vertical farming, compound fertilizer machines are instrumental in formulating nutrient solutions. These machines blend precise ratios of essential macro and micronutrients, ensuring optimal nutrient availability for plants grown in soilless systems. The accurate nutrient composition allows for efficient nutrient uptake, leading to improved crop yields and quality.

Conclusion:

Compound fertilizer machines are indispensable in the production of compound fertilizers, offering precise blending, granulation, coating, and packaging capabilities. These machines find applications in agriculture, horticulture, landscape management, and controlled-environment agriculture. By utilizing compound fertilizer machines, farmers and growers can create customized fertilizers tailored to specific crop and plant requirements, optimizing nutrient management, enhancing productivity, and promoting sustainable agricultural practices.