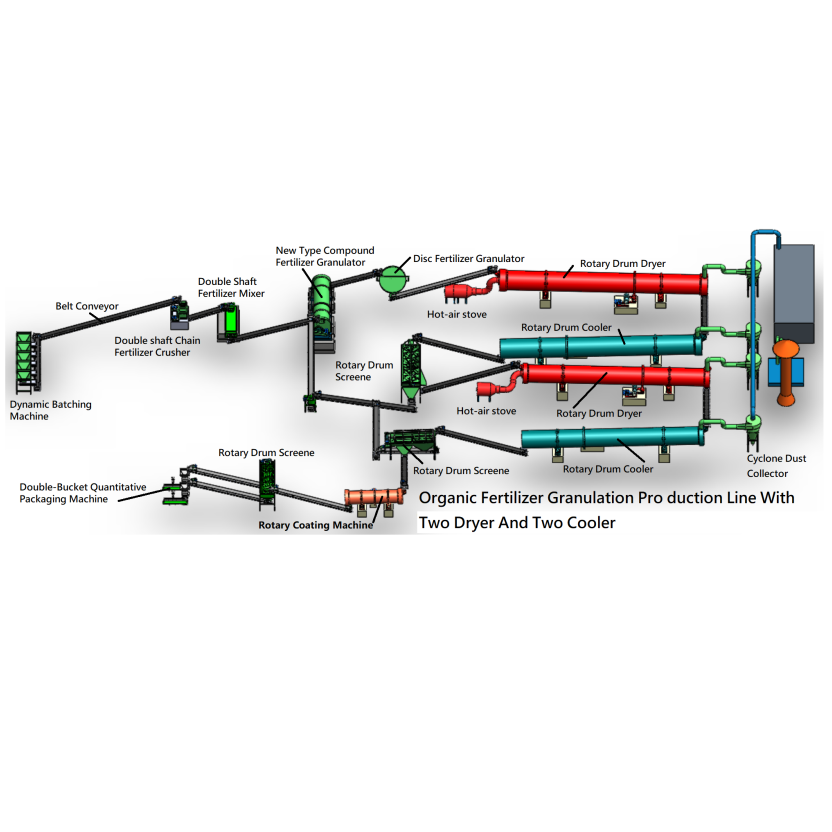

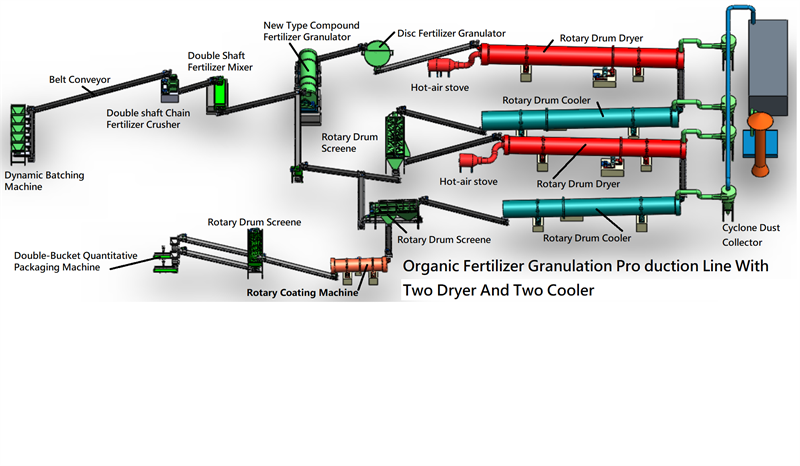

Compound fertilizer equipment production line

The compound fertilizer production line mixes single fertilizers in different proportions, and synthesizes compound fertilizers containing two or more elements of nitrogen, phosphorus and potassium through chemical reactions, with uniform nutrient content and uniform particle size.

Compound fertilizer has the characteristics of uniform granulation, bright color, stable quality, and easy to dissolve and be absorbed by crops. Especially, it is relatively safe for seeds as a seed fertilizer.

It is suitable for all kinds of soil and various crops such as wheat, corn, fruits, peanuts, vegetables, beans, flowers, fruit trees and so on.

Yizheng Heavy Industry is mainly engaged in a complete set of organic fertilizer production lines and a complete set of organic fertilizer equipment. It has a large-scale equipment production base of 80,000 square meters. It supplies various types of organic fertilizer equipment, compound fertilizer equipment and other series of supporting products, and provides professional consulting services.

Organic fertilizer production process:

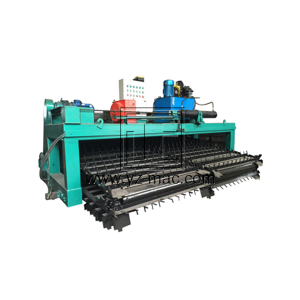

1. fermentation process

Drough-type dumper is the most widely used fermentation equipment. The grooved stacker consists of a fermentation tank, walking track, power system, displacement device and multi-lot system. The overturning part is driven by advanced rollers. Hydraulic flipper can rise and drop freely.

2. granulation process

A new type of organic fertilizer granulator is widely used in organic fertilizer granulation. It is a special granulator for raw materials such as animal excrement, decaying fruits, peels, raw vegetables, green fertilizer, sea fertilizer, farm fertilizer, three wastes, microorganisms and other organic waste materials. It has the advantages of high granulation rate, stable operation, durable equipment and long service life, and is an ideal choice for producing organic fertilizer. The housing of this machine adopts seamless pipe, which is more durable and does not deform. Coupled with the safety dock design, the operation of the machine is more stable. The compressive strength of the new organic fertilizer granulator is higher than that of the disk granulator and drum granulator. The particle size can be adjusted according to customer requirements. The granulator is most suitable for direct granulation of organic waste after fermentation, saving the drying process and greatly reducing production costs.

3. drying and cooling process

The particle moisture content after granulation by the granulator is high, so it needs to be dried to meet the water content standard. The dryer is mainly used to dry particles with certain humidity and particle size in the production of organic fertilizer compound fertilizer. The particle temperature after drying is relatively high, and it should be cooled to prevent fertilizer from clumping. The cooler is used for cooling particles after drying and is used in combination with rotary dryer, which can greatly improve cooling efficiency, reduce labor intensity, increase yield, further remove the moisture of particles and reduce fertilizer temperature.

4. screening process

In production, in order to ensure the uniformity of the finished product, the particles should be screened before packaging. Roller sieving machine is a common sieving equipment in the production process of compound fertilizer and organic fertilizer. It is used to separate finished products and non-conforming aggregates and further achieve the classification of finished products.

5. packaging process

After the packaging machine is activated, the gravity feeder starts to operate, loads the material into the weighing hopper, and puts it into a bag through the weighing hopper. When the weight reaches the default value, the gravity feeder stops running. The operator takes away the packaged materials or puts the packaging bag on the belt conveyor to the sewing machine.

For more detailed solutions or products, please pay attention to our official website:

https://www.yz-mac.com/compound-fertilizer-production-lines/