Compost to fertilizer machine

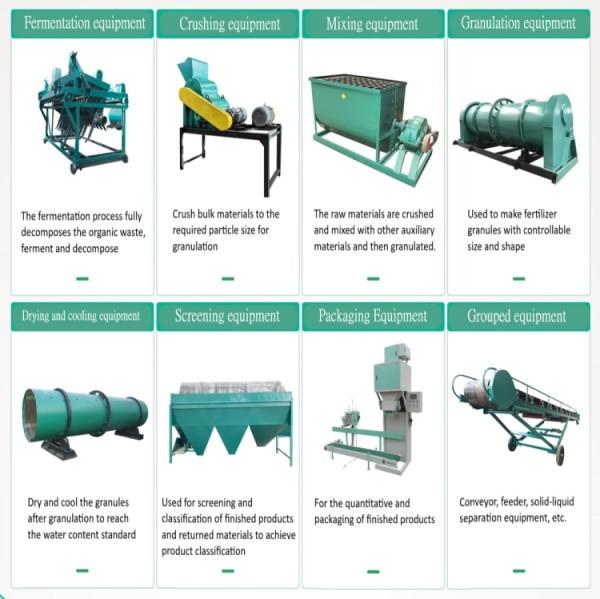

A compost to fertilizer machine is a specialized equipment designed to convert compost into high-quality organic fertilizer. This machine plays a crucial role in the recycling and utilization of organic waste, transforming it into a valuable resource for sustainable agriculture.

Types of Compost to Fertilizer Machines:

Compost Windrow Turners:

Compost windrow turners are large-scale machines used for industrial composting operations. They turn and mix the compost piles, ensuring proper aeration, temperature control, and microbial activity. These machines help accelerate the composting process and produce well-processed compost suitable for fertilizer production.

Compost Granulators:

Compost granulators, also known as compost pellet machines or granulating machines, are used to convert compost into granular fertilizer. They compress and shape the compost into small pellets, making it easier to handle, store, and apply. Compost granulators provide a convenient way to package and distribute organic fertilizers.

Compost Fermentation Tanks:

Compost fermentation tanks, also referred to as biofertilizer fermentation tanks or biofertilizer fermenters, are used for the bioconversion of compost into biofertilizer. These tanks create an ideal environment for beneficial microorganisms to ferment the compost, enriching it with additional nutrients and enhancing its fertilizing properties.

Applications of Compost to Fertilizer Machines:

Agricultural Fertilization:

The primary application of compost to fertilizer machines is in agricultural fertilization. The transformed compost can be used as an organic fertilizer to enrich the soil with essential nutrients, improve soil structure, and enhance crop productivity. The nutrient-rich compost fertilizer provides a sustainable and environmentally friendly alternative to chemical fertilizers.

Horticulture and Gardening:

Compost to fertilizer machines play a vital role in horticulture and gardening. The resulting compost fertilizer can be applied to gardens, flower beds, potted plants, and greenhouse crops to promote healthy growth, improve soil health, and increase plant resistance to diseases and pests. It provides a natural and nutrient-balanced option for plant nutrition.

Landscaping and Turf Management:

Compost-based fertilizers produced by compost to fertilizer machines are widely used in landscaping and turf management. These fertilizers help maintain healthy lawns, sports fields, golf courses, and other landscaped areas. They improve soil fertility, enhance root development, and contribute to a vibrant and lush landscape.

Organic Farming:

Compost to fertilizer machines are essential tools in organic farming practices. Organic farmers utilize the transformed compost as an integral part of their nutrient management strategies. The compost-based fertilizers provide a sustainable approach to soil fertility, promote ecological balance, and maintain the health of organic farming systems.

Soil Remediation and Land Rehabilitation:

Compost to fertilizer machines have applications in soil remediation and land rehabilitation projects. The transformed compost can be used to improve degraded soils, contaminated sites, or areas affected by erosion. It helps restore soil health, rebuild soil structure, and support the establishment of vegetation, facilitating the rehabilitation of land.

Compost to fertilizer machines offer a sustainable solution for transforming compost into nutrient-rich organic fertilizers. Through the utilization of these machines, organic waste materials can be effectively recycled and converted into valuable resources for agriculture and horticulture. The resulting compost fertilizers contribute to soil fertility, plant nutrition, and environmental sustainability. Whether in agricultural fields, gardens, landscaping, or land rehabilitation, compost to fertilizer machines play a vital role in harnessing the potential of compost for sustainable and eco-friendly fertilizer production.