Compost making machines

Compost making machines are specialized equipment designed to effectively convert organic waste into nutrient-rich compost. These machines automate and streamline the composting process, providing an optimal environment for decomposition and microbial activity.

Compost Turners:

Compost turners are machines that help mix and aerate the composting materials. They come in various sizes and configurations, including tractor-mounted, self-propelled, or towable models. Compost turners automate the process of turning the compost pile, ensuring efficient mixing and aeration. They promote faster decomposition and produce high-quality compost.

Compost Shredders:

Compost shredders are used to break down organic waste materials into smaller pieces. These machines are particularly useful for shredding branches, leaves, straw, and other plant matter. Shredding the waste materials increases their surface area, facilitating faster decomposition and microbial activity. Shredded materials are easier to handle and mix in the compost pile.

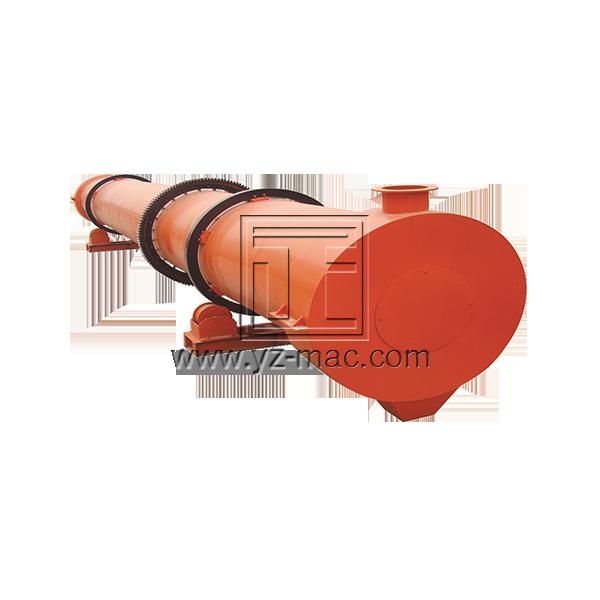

Compost Crushers:

Compost crushers are designed to crush and grind organic waste materials into smaller particles. They are effective in reducing the size of materials such as food scraps, garden waste, and agricultural residues. Crushing the waste materials helps accelerate decomposition and improves the efficiency of the composting process.

Compost Mixers and Blenders:

Compost mixers and blenders ensure the thorough mixing of composting materials. These machines help achieve a homogeneous mixture by blending different components, such as green waste, brown waste, and amendments. Proper mixing ensures uniform decomposition and enhances the quality of the resulting compost.

Compost Granulators:

Compost granulators are used to convert compost into granules or pellets. These machines are commonly employed in the final stages of the composting process. Granulating the compost improves its handling, storage, and application characteristics. Compost granules are easier to store, transport, and spread on gardens, fields, or landscaping projects.

Compost Screeners:

Compost screeners are equipment items used to separate larger or unwanted materials from the compost. They help remove rocks, plastic, and other debris that may be present in the organic waste. Screeners are available in different mesh sizes, allowing for customization based on the desired compost particle size. Separating the compost from larger materials ensures a more refined and higher-quality end product.

Compost Curing Systems:

Compost curing systems provide a controlled environment for the compost to mature and stabilize. These systems often include racks, bins, or vessels designed to maintain proper airflow, temperature, and moisture levels during the curing process. Curing allows the compost to fully mature and develop into a stable, nutrient-rich end product.

Compost Monitoring and Control Systems:

Compost monitoring and control systems utilize sensors and probes to measure and regulate factors such as temperature, moisture, and oxygen levels within the composting system. These systems help ensure optimal composting conditions, allowing for better control and management of the composting process.