Compost large scale

Composting on a large scale refers to the process of managing and processing organic waste materials in significant quantities to produce compost.

Waste Diversion and Environmental Impact:

Large-scale composting offers a sustainable solution for diverting organic waste from landfills. By composting on a large scale, significant amounts of organic waste materials, such as food waste, yard trimmings, agricultural residues, and bio-based products, can be diverted from traditional waste disposal methods. This diversion reduces the environmental impact associated with landfilling, including methane emissions, groundwater contamination, and greenhouse gas production.

Efficient Organic Waste Management:

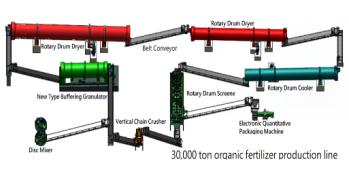

Large-scale composting operations utilize specialized equipment and systems designed to handle substantial volumes of organic waste efficiently. These facilities typically include composting pads, windrows, or aerated static pile systems. The large-scale infrastructure allows for the effective management of organic waste, ensuring proper aeration, moisture control, and decomposition.

Nutrient Recycling and Soil Enrichment:

Large-scale composting facilities produce significant amounts of nutrient-rich compost. This compost can be used to enrich soils, improve soil fertility, and enhance plant growth. By recycling organic waste into compost, large-scale composting contributes to a sustainable and closed-loop approach, minimizing the need for synthetic fertilizers and promoting natural nutrient cycling.

Agricultural and Horticultural Applications:

The substantial quantity of compost produced in large-scale composting operations makes it a valuable resource for agricultural and horticultural applications. The compost can be used as a soil amendment in farming, landscaping, gardening, and reclamation projects. Large-scale composting facilities often collaborate with local farmers, nurseries, and landscaping companies to provide a reliable and high-quality compost product.

Regulatory Compliance and Environmental Standards:

Large-scale composting operations are subject to regulatory compliance and environmental standards to ensure safe and environmentally responsible practices. Compliance with regulations related to organic waste management, air quality, odor control, and water management is crucial for large-scale composting facilities. Implementing effective monitoring systems and adhering to relevant regulations helps maintain operational integrity and public trust.

Conclusion:

Large-scale composting plays a significant role in diverting organic waste from landfills, recycling nutrients, and promoting sustainable waste management practices. It offers efficient organic waste management solutions, economic opportunities, and soil enrichment through the production of nutrient-rich compost. By composting on a large scale, we can reduce environmental impact, close the nutrient loop, and contribute to a more sustainable future.