commercial composter

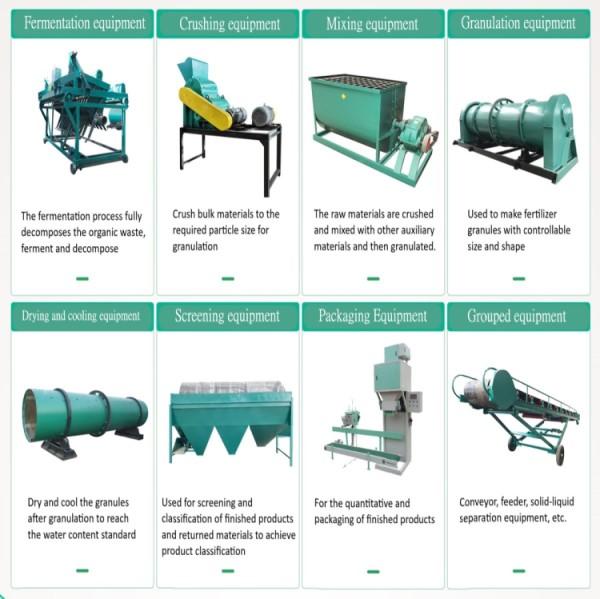

A commercial composter is a type of equipment used to compost organic waste on a larger scale than home composting. These machines are designed to handle large volumes of organic waste, such as food waste, yard waste, and agricultural byproducts, and are typically used in commercial composting facilities, municipal composting operations, and large-scale farms and gardens.

Commercial composters come in a variety of sizes and designs, ranging from small, portable units to large, industrial-scale machines. They typically include features such as mixing and aeration systems, temperature controls, and moisture sensors to ensure that the composting process is optimized for maximum efficiency and nutrient content.

Some commercial composters are designed to produce compost quickly, using high-temperature aerobic composting techniques, while others use slower, cooler composting methods. The specific method used will depend on the type and volume of organic waste being composted, as well as the desired end product.

Using a commercial composter offers several benefits, including reduced environmental impact, improved soil health, and increased crop yields. Additionally, commercial composting helps to reduce the amount of organic waste sent to landfills, which can reduce greenhouse gas emissions and help to mitigate climate change.

When selecting a commercial composter, it is important to consider factors such as the capacity of the machine, the type of waste it can handle, and the level of automation. Prices may vary depending on the specific features and capacity of the machine.