China Cheap price Electronic Quantitative Packaging Machine - Automatic Packaging Machine – YiZheng

China Cheap price Electronic Quantitative Packaging Machine - Automatic Packaging Machine – YiZheng Detail:

Packaging Machine for Fertilizer is used to packing fertilizer pellet, designed for quantitative packing of materials. It includes double bucket type and single bucket type. The machine has the characteristics of integrated structure, simple installation, easy maintain, and quite high quantitative accuracy which is below 0.2%.

With its “fast, accurate and stable” — it has become the first choice for packaging in the fertilizer production industry.

1. Applicable packaging: suitable for knitting bags, sack paper bags, cloth bags and plastic bags, etc.

2. Material: 304 stainless steel is used in the contact part of the material, which has high corrosion resistance.

Automatic packaging machine is a new generation of intelligent packaging machine developed by our company. It mainly consists of automatic weighing device, conveying device, sewing and packaging device, computer control and other four parts. The utility model has the advantages of reasonable structure, beautiful appearance, stable operation, energy saving and accurate weighing. Automatic packaging machine is also known as the computer quantitative packaging scale, the main machine adopts fast, medium and slow three-speed feeding and special feeding mixing structure. It uses advanced digital frequency conversion technology, sampling processing technology and anti-interference technology to realize automatic error compensation and correction.

1. Food categories: seeds, corn, wheat, soybeans, rice, buckwheat, sesame, etc.

2. Fertilizer categories: feed particles, organic fertilizer, fertilizer, ammonium phosphate, large particles of urea, porous ammonium nitrate, BB fertilizer, phosphate fertilizer, potash fertilizer and other mixed fertilizer.

3. Chemical categories: for PVC, PE, PP, ABS, polyethylene, polypropylene and other granular material.

4. Food categories: white, sugar, salts, flour and other food categories.

(1) Fast packaging speed.

(2) The quantitative precision is below 0.2%.

(3) Integrated structure, easy maintenance.

(4) With conveyor sewing machine with a wide quantitative range and high accuracy.

(5) Adopt import sensors and import pneumatic actuators, which work reliably and maintain easily.

1. It has big transport capacity and long transport distance.

2. Stable and highly efficient operation.

3. Uniform and continuous discharging

4. The size of the hopper and the model of the motor can be customized according to the capacity.

| Model | YZBZJ-25F | YZBZJ-50F |

| Weighing Range (kg) | 5-25 | 25-50 |

| Accuracy (%) | ±0.2-0.5 | ±0.2-0.5 |

| Speed (bag/hour) | 500-800 | 300-600 |

| Power (v/kw) | 380/0.37 | 380/0.37 |

| Weigh (kg) | 200 | 200 |

| Overall Size (mm) | 850×630×1840 | 850×630×1840 |

Product detail pictures:

Related Product Guide:

Pig manure organic fertilizer complete equipment

Compound fertilizer production process

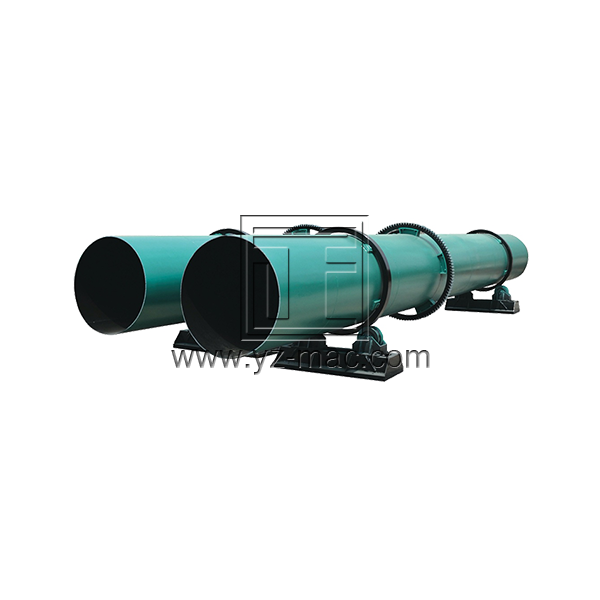

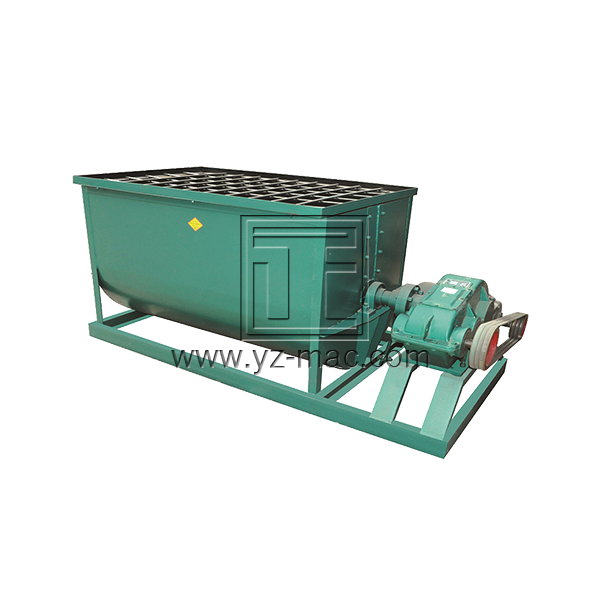

The double-screw turning machine is used for the fermentation and turning of organic wastes such as livestock and poultry manure, sludge waste, sugar mill filter mud, slag cake and straw sawdust. It is suitable for aerobic fermentation and can be combined with solar fermentation chamber, Fermentation tank and moving machine are used together. China Cheap price Electronic Quantitative Packaging Machine - Automatic Packaging Machine – YiZheng , The product will supply to all over the world, such as: Costa rica, Tanzania, Rome, The industrial composting screening machine is composed of a motor, a reducer, a drum device, a frame, a sealing cover, and an inlet and outlet. The granulated organic fertilizer granules should be screened to obtain the desired granule size and to remove granules that do not meet the fineness of the product.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!