Chicken manure fertilizer screening equipment

Chicken manure fertilizer screening equipment is used to separate the finished fertilizer pellets into different sizes or grades based on their particle size. This equipment is essential to ensure that the fertilizer pellets meet the desired specifications and quality standards.

There are several types of chicken manure fertilizer screening equipment, including:

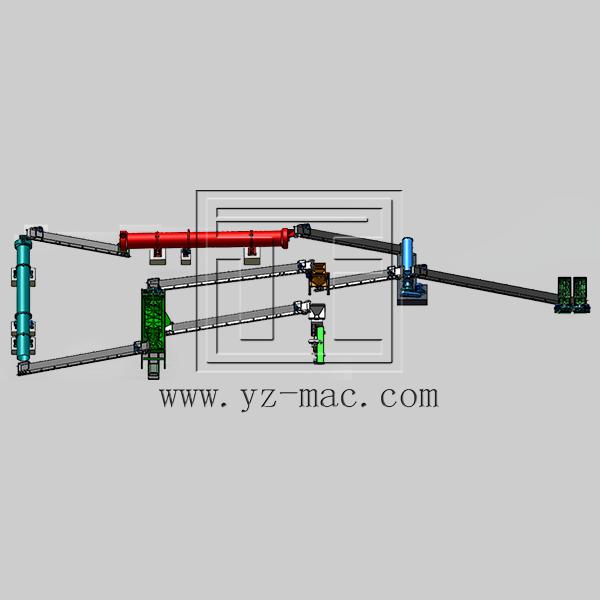

1.Rotary Screener: This equipment consists of a cylindrical drum with perforated screens of different sizes. The drum rotates and the fertilizer pellets are fed into it. The pellets are then separated by size as they move through the drum, with the smaller pellets passing through the smaller screens and the larger pellets being retained on the larger screens.

2.Vibrating Screen: This equipment uses a vibrating motor to shake the screen and separate the fertilizer pellets based on size. The pellets are fed onto the screen, and the smaller particles pass through the screen while the larger particles are retained.

3.Drum Screener: This equipment is similar to the rotary screener, but it has a fixed drum with perforated screens of different sizes. The drum rotates, and the fertilizer pellets are fed into it. The pellets are then separated by size as they move through the drum.

The specific type of chicken manure fertilizer screening equipment required will depend on the production capacity, the desired particle size distribution, and the specific requirements of the end product. It is important to select the appropriate equipment for efficient and effective screening of the chicken manure fertilizer pellets.