Chain plate Compost Turning

The Chain Plate Composting Turner Machine has reasonable design, less power consumption of motor, good hard face gear reducer for transmission, low noise and high efficiency. Key parts such as: Chain using high quality and durable parts. Hydraulic system is used for lifting and lowering, and the turnover depth can reach 1.8-3 meters. Material vertical lifting height can reach 2 meters, stay in the air for a long time, without aeration, other forms of dumper can do three fermentation tanks, using Chain Plate Composting Turner Machine, one is enough.

1. Using chain drive, rolling support of the pallet structure, flip resistance to save energy, suitable for deep groove operation.

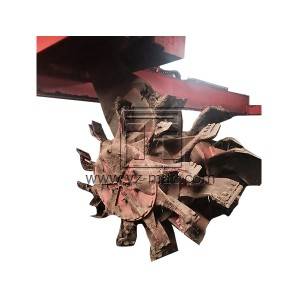

2. Flip-up pallet is equipped with flexible tension and elastic damping system to protect the drive system and working parts and efficient operation.

3. Flip-throwing pallet is equipped with removable wear-resistant curved tooth blade, crushing ability, material reactor oxygen effect.

4. The material stay in the pallet for a long time, high scattered, and air contact with the full, easy precipitation.

5. Horizontal and vertical displacement can be achieved anywhere in the slot flip operation, flexible mobility.

6. The lifting part use hydraulic control system, flexible work, safe and efficient.

7. Long-range remote control of the aircraft forward, horizontal shift, flip and fast back and other operations to improve the operating environment.

8. Optional slot material feeder, automatic discharge device, solar fermentation room and ventilation aeration system.

9. Combines functions of turning material, regulating porosity, supplying oxygen, and material transposition.

10. Automatic control system with safety switch and remote control.

11. Equipped with a slot-shift device can realize a slotting machine multi-slot operation, saving investment.

The running system of Chain Plate Composting Turner Machine adopts variable frequency speed regulation, which has good adaptability to different materials, stable running, high turning efficiency and deep groove operation. It can shorten the fermentation period and improve the production efficiency and product quality. Using variable frequency speed walking system, can well adapt to changes in workload.

|

No. |

Parameter Name |

Unit |

Model |

||

|

YZFJLB-30 |

YZFJLB-40 |

YZFJLB-50 |

|||

|

1 |

Power |

kw |

19 |

20.5 |

30 |

|

2 |

Chain plate width |

mm |

3000 |

4000 |

5000 |

|

3 |

Speed of work |

m/h |

Adjustable |

Adjustable |

Adjustable |

|

4 |

No-load Speed |

m/h |

Adjustable |

Adjustable |

Adjustable |

|

5 |

Width of the fermentation tank |

mm |

3380 |

4380 |

5380 |

|

6 |

Height of the fermentation tank |

mm |

1500 |

1500 |

2000 |

|

7 |

Material height |

mm |

1300 |

1300 |

1800 |

|

8 |

Maximum turning ability |

m³/h |

|

|

|

|

9 |

Material displacement of each turning |

m |

4 |

4 |

4.5 |

|

10 |

Maximum lifting height |

m |

2.5 |

2.5 |

3.4 |