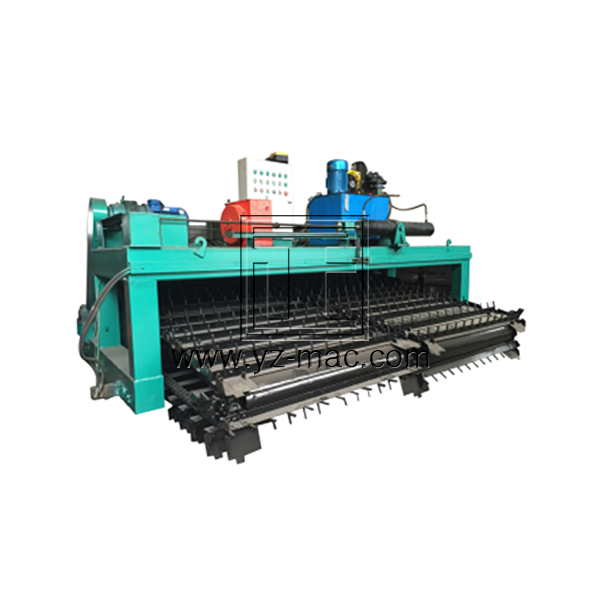

Best Price for Fertilizer Granulating Machine - New Type Organic & Compound Fertilizer Granulator Machine – YiZheng

Best Price for Fertilizer Granulating Machine - New Type Organic & Compound Fertilizer Granulator Machine – YiZheng Detail:

The New Type Organic & Compound Fertilizer Granulator Machine makes use of the aerodynamic force generated by the high-speed rotating mechanical stirring force in the cylinder to make the fine materials continuous mixing, granulation, spheroidization, extrusion, collision, compact and strengthen, finally become into granules. The machine is widely used in the production of high nitrogen content fertilizer such as organic and inorganic compound fertilizer.

The New Type Organic & Compound Fertilizer Granulator Machine use high-speed rotating mechanical force to make the fine powder materials continuous mixing, granulating, spheroidizing and density, so as to achieve the goal of the granulation. The shape of particles is spherical, the spherical degree is 0.7 or higher, the particle size is generally between 0.3 and 3 mm and the granulating rate is up to 90% or higher. The size of particle diameter can be adjusted according to the mixture quantity and spindle rotational speed, generally, the lower the mixing volume, the higher the rotational speed, the smaller the particle size.

- ►High Granulation Rate

- ►Low Energy Consumption

- ►Simple Operation

- ►The shell is made of thickened spiral steel tube, which is durable and never deforms.

The capacity of New Type Organic & Compound Fertilizer Granulation Production Line ranges from 10,000 tons per year to 300,000 tons per year.

The components of complete fertilizer production line

1) Electronic belt scale

2) Mixing machine or grinding machine, various options based on process requirements

3) Belt conveyor and bucket elevator

4) Rotary granulator or disc granulator, various options base on process requirements

5) Rotary dryer machine

6) Rotary cooler machine

7) Rotary sieve or vibrating sieve

8) Coating machine

9) Packing machine

1) The whole Granulation Production Line is our mature products, they are running stable, the quality of them is high, and they are easy to maintenance and repair.

2) The rate of being ball is high, outer recycle materials is few, the comprehensive energy consumption is low, no pollution and strong adaptability.

3) The setting of the whole production line is reasonable and within advanced technology, it could improve production efficiency, reducing the production cost and the production scale could be controlled easily.

|

Model |

Bearing Model |

Power (KW) |

Overall Size (mm) |

|

YZZLHC1205 |

22318/6318 |

30/5.5 |

6700×1800×1900 |

|

YZZLHC1506 |

1318/6318 |

30/7.5 |

7500×2100×2200 |

|

YZZLHC1807 |

22222/22222 |

45/11 |

8800×2300×2400 |

Product detail pictures:

Related Product Guide:

Complete production equipment for organic fertilizer

Pig manure organic fertilizer complete equipment

The fermentation tank is mainly used for high-temperature aerobic fermentation of livestock and poultry manure, kitchen waste, domestic sludge and other wastes, and uses the activity of microorganisms to biodecompose the organic matter in the waste, so that it can be harmless, stabilized and reduced. Integrated sludge treatment equipment for quantitative and resource utilization. Best Price for Fertilizer Granulating Machine - New Type Organic & Compound Fertilizer Granulator Machine – YiZheng , The product will supply to all over the world, such as: Hungary, Southampton, Nepal, Double roller granulator machine

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.