Compound fertilizer, also known as chemical fertilizer, is a fertilizer containing any two or three nutrients of crop nutrients, such as nitrogen, phosphorus and potassium, synthesized by chemical reactions or mixing methods; compound fertilizers can be powdery or granular. Composite fertilizer contains high active ingredients, is easy to soluble in water, decomposes quickly, and is easy to be absorbed by roots. Therefore, it is called "quick-acting fertilizer". Its function is to meet the comprehensive demand and balance of a variety of nutrients in different production conditions.

The annual production line of 50,000 tons of compound fertilizer is a combination of advanced equipment. Production costs are inefficient. Compound fertilizer production line can be used for granulation of various composite raw materials. Finally, compound fertilizers with different concentrations and formulas can be prepared according to actual needs, effectively replenish the nutrients needed by crops, and solve the contradiction between crop demand and soil supply.

Composite Fertilizer Production Line is mainly used to produce compound fertilizers of different formulas such a potassium s nitrogen, phosphorus potassium perphosphate, potassium chloride, granular sulfate, sulfuric acid, ammonium nitrate and other different formulas.

As a professional manufacturer of fertilizer production line equipment, we provide customers with production equipment and the most suitable solution for different production capacity needs such as 10,000 tons per year to 200,000 tons per year. The complete set of equipment is compact, reasonable and scientific, with stable operation, good energy-saving effect, low maintenance cost and convenient operation. It is the most ideal choice for compound fertilizer (mixed fertilizer) manufacturers.

Composite fertilizer production line can produce high, medium and low concentration compound fertilizer from various crops. Generally speaking, compound fertilizer contains at least two or three nutrients (nitrogen, phosphorus, potassium). It has the characteristics of high nutrient content and few side effects. Compound fertilizer plays a vital role in balanced fertilization. It can not only improve the fertilization efficiency, but also promote the stable and high yield of crops.

Application of compound fertilizer production line:

1. Production process of sulfur-baged urea.

2. Different production processes of organic and inorganic compound fertilizers.

3. Acid fertilizer process.

4. Powdered industrial inorganic fertilizer process.

5. Large-grained urea production process.

6. Production process of matrix fertilizer for seedlings.

Raw materials available for organic fertilizer production:

The raw materials of the compound fertilizer production line are urea, ammonium chloride, ammonium sulfate, liquid ammonia, ammonium phosphate, diammonium phosphate, potassium chloride, potassium sulfate, including some clays and other fillers.

1) Nitrogen fertilizers: ammonium chloride, ammonium sulfate, ammonium thio, urea, calcium nitrate, etc.

2) Potassium fertilizers: potassium sulfate, grass and ash, etc.

3) Phosphorus fertilizers: calcium perphosphate, heavy calcium perphosphate, calcium magnesium and phosphate fertilizer, phosphate ore powder, etc.

Composite fertilizer production line rotary drum granulation is mainly used to produce high-concentration compound fertilizer. Round disk granulation can be used to produce high- and low-concentration compound fertilizer technology, combined with compound fertilizer anti-congested technology, high-nitrogen compound fertilizer production technology, etc.

The compound fertilizer production line of our factory has the following characteristics:

Raw materials are widely used: compound fertilizers can be produced according to different formulas and proportions of compound fertilizers, and are also suitable for the production of organic and inorganic compound fertilizers.

The minimum spherical rate and biobacterium yield are high: the new process can achieve a spherical rate of more than 90% to 95%, and the low-temperature wind drying technology can make the microbial bacteria reach a survival rate of more than 90%. The finished product is beautiful in appearance and even in size, 90% of which is particles with a particle size of 2 to 4mm.

The labor process is flexible: the process of the compound fertilizer production line can be adjusted according to the actual raw materials, formula and site, or the customized process can be designed according to the actual needs of customers.

The proportion of nutrients of finished products is stable: through automatic measurement of ingredients, accurate measurement of various solids, liquids and other raw materials, almost maintaining the stability and effectiveness of each nutrient throughout the process.

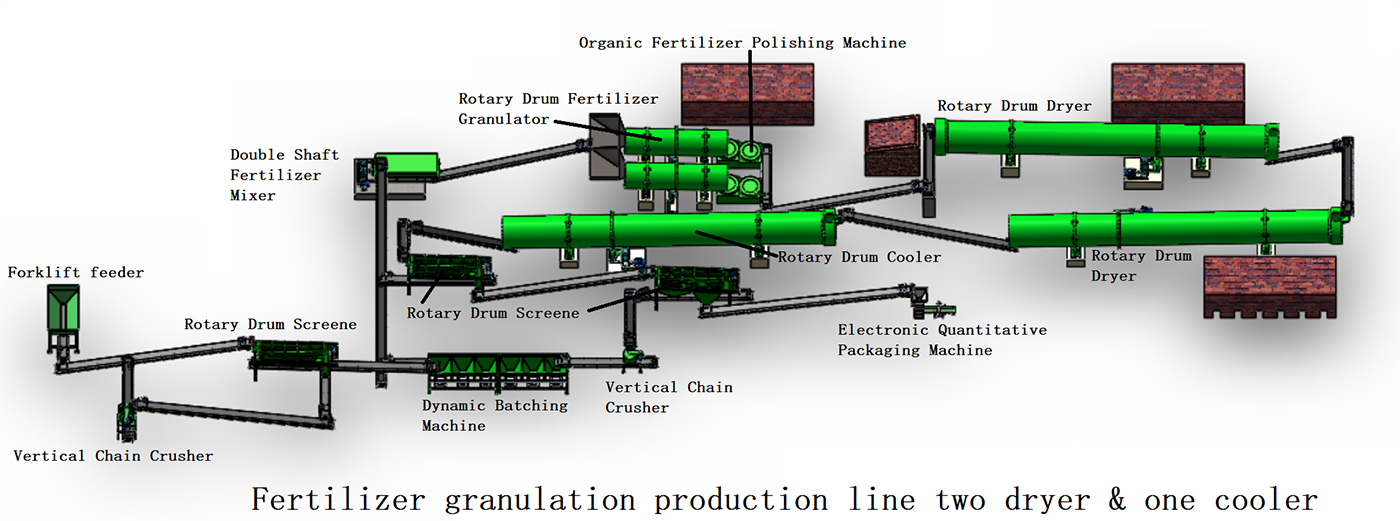

The process flow of the composite fertilizer production line can usually be divided into: raw material ingredients, mixing, crushing of nodules, granulation, initial screening, particle drying, particle cooling, secondary screening, finished particle coating, and quantitative packaging of finished products.

1. Raw material ingredients:

According to market demand and local soil determination results, urea, ammonium nitrate, ammonium chloride, ammonium thiophosphate, ammonium phosphate, diammonium phosphate, heavy calcium, potassium chloride (potassium sulfate) and other raw materials are distributed in a certain proportion. Additives, trace elements, etc. are used as ingredients in a certain proportion through belt scales. According to the formula ratio, all raw material ingredients are evenly flowed from belts to mixers, a process called premixes. It ensures the accuracy of the formulation and achieves efficient continuous ingredients.

2. Mix:

The prepared raw materials are fully mixed and stirred evenly, laying the foundation for high-efficiency and high-quality granular fertilizer. A horizontal mixer or disk mixer can be used for uniform mixing and stirring.

3. Crush:

The lumps in the material are crushed after mixing evenly, which is convenient for subsequent granulation processing, mainly using chain crusher.

4. Granulation:

The material after mixing evenly and crushed is transported to the granulation machine through a belt conveyor, which is the core part of the composite fertilizer production line. The choice of granulator is very important. Our factory produces disk granulator, drum granulator, roller extruder or compound fertilizer granulator.

5. Screening:

The particles are sieved, and the unqualified particles are returned to the upper mixing and stirring link for reprocessing. Generally, a roller sieve machine is used.

6. Packaging:

This process adopts an automatic quantitative packaging machine. The machine is composed of an automatic weighing machine, a conveyor system, a sealing machine, etc. You can also configure hoppers according to customer requirements. It can realize the quantitative packaging of bulk materials such as organic fertilizer and compound fertilizer, and has been widely used in food processing factories and industrial production lines.