Bucket Elevator

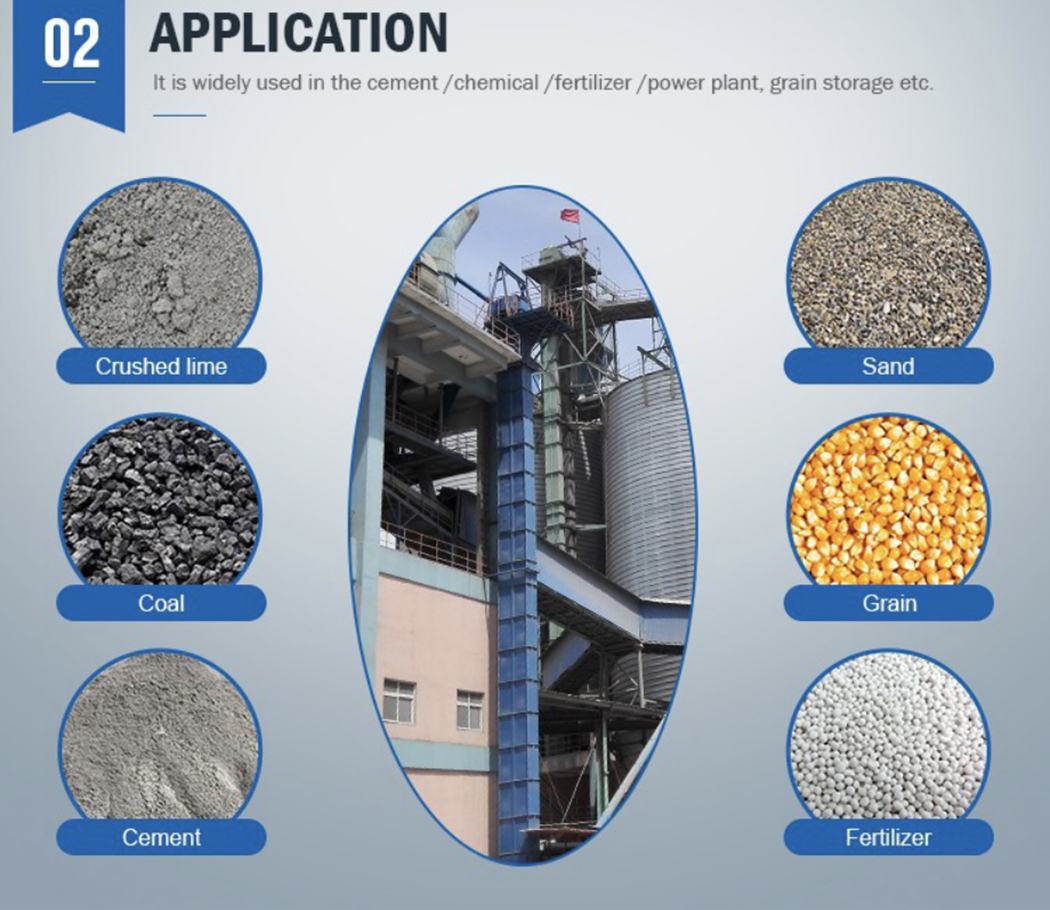

Bucket elevators can handle a variety of materials, and therefore are used in many different industries and applications, though generally, they are not suited for wet, sticky materials, or materials that are stringy or tend to mat or agglomerate. They are frequently found in power plants, fertilizer plants, pulp & paper mills, and steel production facilities.

This series bucket elevator is independently developed by Yizheng and is a fixed installation mainly used for the vertical continuous conveying of powdery materials or granular materials. The equipment is of straightforward structure, compact design, good sealing performance, easy installation and maintenance, allowing positive and reverse material feeding, as well as flexible process configuration and layout.

This series bucket elevators are available in direct coupling drive, sprocket driven or gear reducer drive, delivering straightforward structure and easy arrangement. The installation height is optional, but the maximum height elevator not beyond 40m.

* 90-degree conveying

* Stainless steel contact parts

* Safety tool-less removal of buckets

* Automatic stop & start sensor control with filling from hopper or to scale

* Easy to operate & easy to clean

* Caster for easy positioning

* Wide range of options including indexing, feeders, covers, multiple discharge locations, etc.

|

Model |

YZSSDT-160 |

YZSSDT-250 |

YZSSDT-350 |

YZSSDT-160 |

||||

|

S |

Q |

S |

Q |

S |

Q |

S |

Q |

|

|

Conveying Capacity (m³/h) |

8.0 |

3.1 |

21.6 |

11.8 |

42 |

25 |

69.5 |

45 |

|

Hopper Volume(L) |

1.1 |

0.65 |

63.2 |

2.6 |

7.8 |

7.0 |

15 |

14.5 |

|

Pitch(mm) |

300 |

300 |

400 |

400 |

500 |

500 |

640 |

640 |

|

Belt Width |

200 |

300 |

400 |

500 |

||||

|

Hopper Moving Speed (m/s) |

1.0 |

1.25 |

1.25 |

1.25 |

||||

|

Transmission Rotating Speed (r/min) |

47.5 |

47.5 |

47.5 |

47.5 |

||||